On March 10th, the 17th China International Powder Metallurgy, Cemented Carbide and Advanced Ceramics Exhibition (PM CHINA) was grandly opened in Shanghai World Expo Exhibition & Convention Center. (hereinafter referred to as "SANDI") brought BJ binder jet metal/ceramic and SLM gradient metal 3D printing solutions to the exhibition.

Photo: SANTI TECHNOLOGY live demonstration of BJ Binder Jet Metal Printer 3DPTEK-J160R

During the same period of the exhibition, SANDI Technology shared the theme report "Binder Jet 3D Printing Empowers Powder Metallurgy" at the Injection Molding Forum. The report pointed out that traditional powder injection molding (MIM) faces challenges such as high upfront investment, high cost of mold opening, and limited product sizes, while SANDI Technology realizes mold-less manufacturing, complex structures and large-size molding through binder jet 3D printing (BJM) technology, which provides powder metallurgy industry with a more efficient and low-cost solution.

BJ Binder Jet Metal/Ceramic Printing Solutions

3DPTEK independently masters the key technologies of BJ technology equipment, materials and process, and has mature technology and experience in small particle size powder laying, powder bed density enhancement, high dimensional accuracy control, binder material system development, and degreasing sintering process. The company's self-developed 3DPTEK-J160R/J400P/J800P serialized binder jet printing equipment and its molding process integrates a precise feeding system, a high density powder laying system and a high-precision inkjet printing control system, which solves the key common technologies of small particle size and low mobility powder laying and molding density and breaks through the key technologies of high-resolution and high-precision inkjet control, and can realize 800-1200dpi high-resolution printing and molding, molding accuracy is better than ±0.1mm, molding efficiency up to 3600cc/h, the relevant technical indicators have reached the international advanced level.

Figure: BJ Metal/Ceramic Printer 3DPTEK-J160R, 3DPTEK-J400P/J800P

Meanwhile, SANDI Technology has gradually formed a sound molding process system for binder materials in years of BJ technology research. Based on more than 20 kinds of process formulas formed by two major types of water-based environmentally friendly binder and solvent-based high-efficiency binder, the company develops corresponding molding process and post-treatment process such as degreasing and sintering, realizing the molding process applicable to stainless steel, industrial mold steel, titanium alloy, copper alloy, high-temperature alloys, hard alloys and other metal materials, ceramic materials such as silicon carbide (SiC), as well as PMX crystalline waxes, inorganic salts, foodstuffs, medicines, polymers, composite materials and other non-metallic materials. Composite materials and other non-metallic materials molding process. Meanwhile, through the systematic research on high density degreasing and sintering molding process, we have realized the shape and property control of metal and ceramic products in the process of degreasing and sintering, and precisely controlled the quality of the finished products after degreasing and sintering, and the performance of the products is better than that of the mechanical properties of the MIM international material standard.

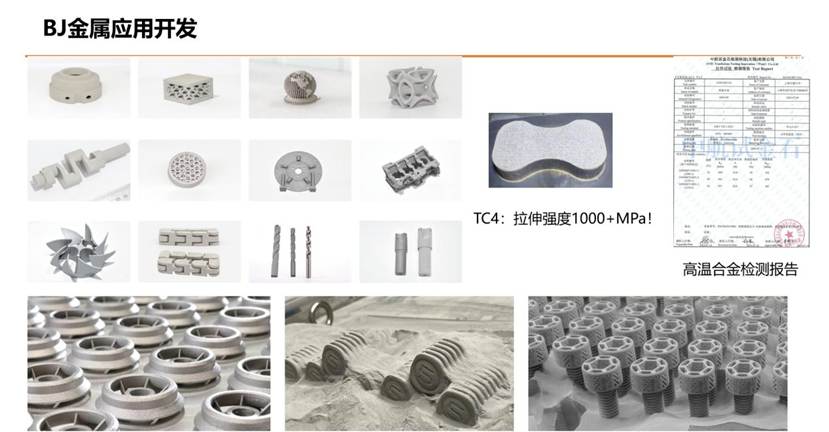

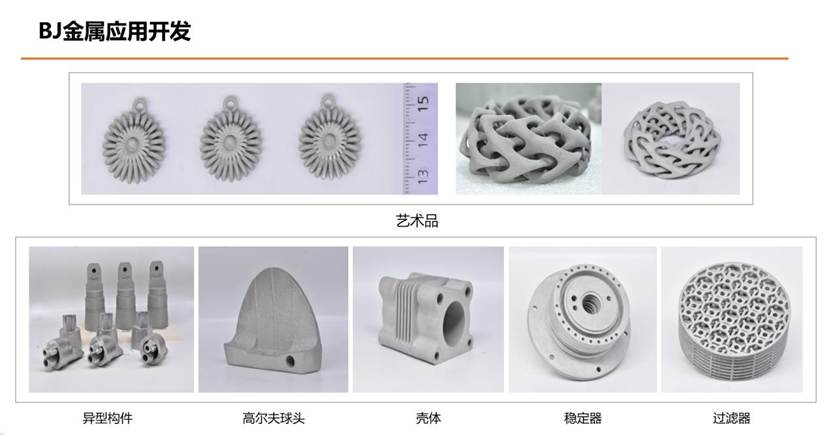

Figure: BJ Metal Printing

Figure: BJ Ceramic Printing

In addition, the three emperor technology joint Shenzhen Vocational Technical University, Shenzhen Tsinghua University Research Institute, Shanghai Jiao Tong University, University of Science and Technology Beijing and other research institutes related to the team to jointly carry out binder injection molding and other materials, process and application of basic technology research, to promote the industrialization of industrial molds, cutting tools, 3C electronics and other products, as well as complex and shaped large-size ceramic products in the field of industrialization and application.

SLMLaser Metal Printing Solutions

SANDI Technology has independently developed and launched SLM Selective Laser Melting Metal Printing Equipment AFS-M120/M400, Gradient Metal Equipment AFS-M120X(T), and Multi-material Increase/Decrease Equipment AFS-M300XAS, etc., and completed the molding of stainless steel/titanium alloys/aluminum alloys/mold steels/cobalt-chrome alloys/nickel-based alloys and other materials and process development.

Figure: SANDY Technology SLM (gradient) metal printing series equipment

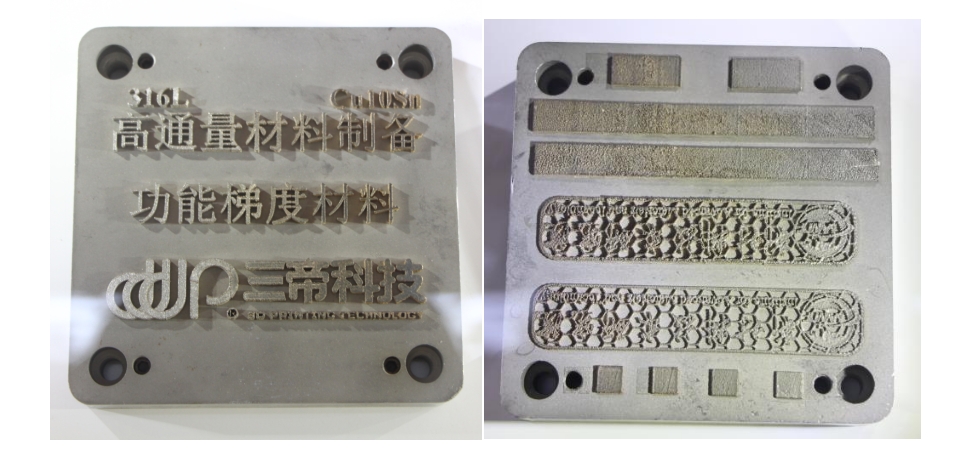

Among them, the gradient metal printing equipment AFS-M120X(T) can be applied to the research and development of the properties of composite metal materials, and it can realize the continuous gradient accurate powder supply of two and more kinds of metal materials; it has the horizontal/vertical gradient change direction, which reduces the complexity of the process, saves the raw materials of the powder, and enhances the efficiency of research and development. It has a broad application prospect in the development of new materials in high throughput material preparation, aerospace, automotive, medical, mold processing and other fields. Multi-material additive and subtractive gradient metal AFS-M300XAS can be applied to the research and development of the properties of composite metal materials, up to 4 kinds of material gradient, the horizontal direction to achieve a continuous gradient change, the vertical direction to achieve the material composition switching or gradient change.

At present, SANDI has cooperated with many research institutes such as University of Science and Technology Beijing, Shandong University of Science and Technology, Lanzhou University of Science and Technology, Beijing University of Aeronautics and Astronautics, Beijing Iron and Steel Research Institute, Shenyang Institute of Automation, etc., and has been continuously providing advanced, reliable, and practical solutions for gradient functional metal materials.

Learn more about 3D Printing Enabled Powder Metallurgy Solutions, March 11-12, Shanghai World Expo Exhibition & Convention CenterSANDY TECHNOLOGY Booth: Hall H1, A735Welcome to the exchange!