Beijing SANDI Technology Co., Ltd. specializes in 3D printing equipment and additive manufacturing services, is theNational Specialized, Specialized and New "Small Giant" Enterprises, Typical Application Scenario Supplier of Additive Manufacturing of MIITTheIt also owns laser and binder jet 3D printing equipment and material technology and application process, and the product technology is mainly used to empower the casting industry and MIM industry. The business covers R&D and production of 3D printing equipment, R&D and production of 3D printing raw materials, and 3D printing process technology support services,Rapid Prototyping Servicesetc., has established a complete 3D printing rapid manufacturing industry chain.(Hotline: Manager Han 13811566237)

SANDI's self-developed industrial casting field for the3DP Inkjet Sand 3D Printer, SLS Selective Laser Sintering Sand/Wax 3D PrinterThe company is a blend of theNearly 30 years of experience in powder laying technologyThe company can meet the needs of manufacturing products of different sizes and materials.The

3DP Inkjet Sand 3D Printer

SANDI Technology 3DP inkjet sand 3D printer molding size, high printing efficiency, sand precision and strength than the traditional process, suitable for large size, complex structure, small and medium batch sand rapid manufacturing.

Application Cases

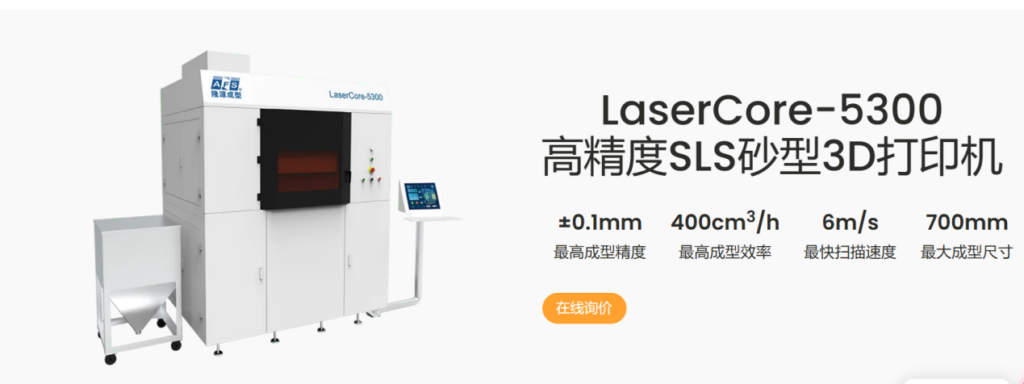

SLS Selective Laser Sintered Sand 3D Printer

SANDI Technology SLS selective laser sintering sand 3D printer is suitable for one-piece molding of complex pipeline and oil pipeline structure sand mold. The precision of the printed sand mold can reach ±0.1mm and the strength can reach 4-6MPa.

SLS Selective Laser Sintering Wax 3D Printer

SANDI Technology SLS Selective Zone Laser Sintering Wax 3D Printer can rapidly mold large-size, thin-walled structure wax patterns with high molding precision and excellent surface quality.

SANDY Technology 3D printing technology empowers casting

Primary value:

1. Enhancement of new product development capabilities

-No need to open metal molds, reduce the cost of new product development and shorten the production cycle;

-Enhance the enterprise's ability to develop new products and new customers and grab orders for bulk orders.

2. Fast delivery of small quantities:

-Low-cost and high-efficiency production of small-lot products through 3D printing or a combination of 3D printing and traditional processes (outer mold: metal mold/wood mold; sand core: 3D printing).

3. Reduce process validation risk:

-Process validation before opening metal molds reduces risk of failure and mold repair time.

4. Rapid manufacturing of metal molds:

-Rapidly manufacture metal molds (aluminum molds, iron molds, etc.) through 3D casting process, which can shorten the manufacturing cycle of metal molds and reduce the manufacturing cost of 20% or more.

5. Optimize the process and improve the technical level:

-Satisfy the demand for lightweight, complex structural products, realize integrated molding, parts manufacturing into components manufacturing, help casting enterprises to enhance the level of technology, improve the added value of products, enhance the profitability of enterprises.

6. Improve material utilization:

-Improve casting material utilization and reduce resource consumption.

7. Enhance the corporate image and improve the production environment:

-Reduces labor intensity and eases recruitment challenges.

Collaborative Advantage:

As a leader and application promoter of 3D printing technology, SANDY TECH.Has received investment support from well-known funds such as Jinke Junchuang, Zhongjin Capital, Zhongke Haichuang and Become Capital.The

Industry Applications

Hotline: Manager Han 13811566237