China is a foundry country, casting production in 2021 reached 51.3 million tons, the industry scale ranks first in the world. China Foundry Association data statistics show that the existing 26,000 domestic foundries, including sand castings market size of about 120 billion yuan. However, in recent years, the development of the industry is facing difficulties, energy saving and emission reduction pressure, shortage of skilled workers, serious homogenization of competition and other issues come to the fore. In order to get out of the dilemma, enterprises have invested a lot of money in new product development and technological transformation, and with the slowdown in the growth rate of economic development, attenuation of the demographic dividend and rising comprehensive costs, the casting industry, the overall reduction in the value-added products, industrial transformation and upgrading of the pace of slowing down the urgent need to explore a new road of transformation and development. Traditional technology has been unable to change the situation, there is an urgent need for many foundry enterprises "innovation and empowerment" of the new technology - at a lower cost, predictable returns, build enterprise product technology from low-end to high-end conversion of the "Green Channel".

In this context, 3DP sand printing technology (also known as "binder jet sand 3D printing technology") into the people's field of vision, after years of development and maturity, has been very competitive. In this paper, we can see the domestic sand 3D printing equipment appeared in the production line of a private casting enterprise in Xianyang City, Shaanxi Province, for their casting products to give the "asymmetric competition" technical advantages, and successfully enter the high-end casting market.

Sand casting and forging, extrusion, welding, milling and other metal processing technology, compared with the most simple and efficient metal molding technology, so it is widely used. Traditional sand casting is mainly used in mold turning sand or core box way modeling, need to make wooden molds or metal molds, manufacturing molds is time-consuming, costly and risky, so that many foundry companies in the early stages of new product development is faced with the dilemma of choice - if the molds are opened and can not get the order, it will be a loss of mold fees for nothing. In this case, in addition to new product development, some small quantities of parts, complex parts of the demand is also difficult to meet. On the other hand, the mold sand itself has many process shortcomings, such as mold assembly and demolding for the assembly margin reserved for mold assembly and demolding tilt margin, resulting in sand casting products processing removal of a larger amount of high dimensional error, casting surface finish is poor and other issues. Therefore, the higher quality requirements of complex castings have to give up the sand casting process, and turn to other more costly alternative processes, such as pressure casting, precision casting, etc..

The emergence of 3DP sand printing technology can largely change the unfavorable situation that sand casting is in. The use of 3DP sand printing technology does not require molds, direct printing of sand, can be completed with the minimum time and minimum cost of new product development and delivery of small and medium volume products. After 3DP process validation, the casting process can be perfected, the contract was successfully signed, and then invested in opening molds for large-volume manufacturing, which can save a lot of investment in molds. In terms of quality, 3DP sand type is not subject to the constraints of the mold sand turning process, with 10 micron level of high precision, complex structure of one free molding, part of the cast aluminum casting surface accuracy can be comparable to the precision casting, but also reduces the assembly errors caused by the scrap rate, reducing the labor of workers, the overall economic benefits are very significant.

In recent years, driven by both technology and market demand, China's 3DP sand printing technology has developed rapidly. Beijing Longyuan Automatic Forming System Co., Ltd (a subsidiary of SANDI Technology, referred to as "Longyuan Forming"), a leading domestic 3D printing equipment and manufacturing service provider, has independently developed and launched AFS-J1600 and AFS-J2100 series of mass production equipment, which has realized a printing speed of less than 15s/layer and passed the 1000-hour equipment stability test, with good printing accuracy and intrinsic quality. The equipment has passed the 1000-hour stability test, has good printing accuracy and inherent quality, and is designed to meet the needs of aluminum, iron, magnesium, steel and other applications, with a wide range of abrasive systems and binder materials.

Ltd. introduced two sets of Longyuan Molding 3DP sand printers for sand production in 2021, which have now completely replaced the wooden mold sand turning process. It not only saves the cost and time of mold opening, but also avoids the risk caused by unreasonable mold design and mold repair. The production efficiency has been greatly improved, especially for the trial production of high value-added products with short cycle time, high precision and small batch, which can be delivered with high quality and high efficiency with greater ease, and has become a major competitive advantage.

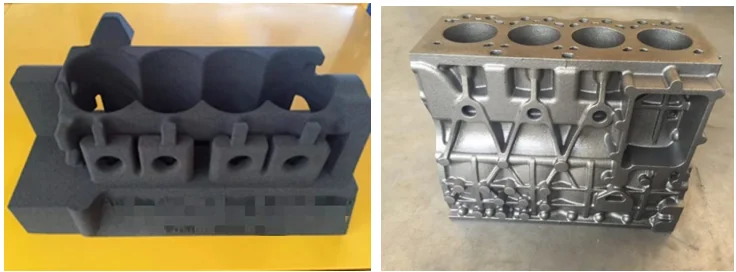

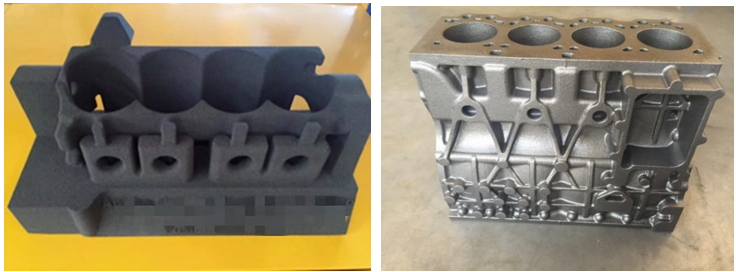

Xinxin casting through Longyuan molding 3DP sand printer using sand rapid casting process for a car factory trial production of engine block, due to the complexity of the cylinder structure, and wall thickness is small, if the traditional method of production cycle takes more than 1 month. 3DP sand printing equipment produced by the sand, precision and strength than the traditional process have been greatly improved, the tensile strength of up to 2MPa, the surface roughness of the casting below Ra12.5, defects are well controlled, no succulent, porosity, cracks, slag entrapment, no surface defects and defects. It only took 10 days to deliver the finished castings of gray cast iron (HT250), the production cycle was shortened by 2/3, and the cost was reduced by 30%.

Xinxin Casting adopts sand rapid casting process through Longyuan molding 3DP sand printer to try to produce lightweight frame for a new energy vehicle enterprise, if the traditional method is used to produce, the production cycle will take 40 days. By using 3DP sand printing rapid casting, the dimensional accuracy of the final molded casting reaches CT7 level, the surface roughness is lower than Ra12.5μm, the surface of the casting is free of porosity and cracks, the shape of the casting is complete and the structure is clear. The final aluminum alloy (ZL101) finished castings were delivered in 6 days, shortening the production cycle by 85% and reducing the cost by 32%.

Xin Xin casting responsible person Tan Dawei said, now more orders to do over, two 3DP sand printer 24 hours on continuous operation, the current monthly printing capacity of 20 tons of sand has been far from meeting the huge market demand. Xinxin Casting will introduce more 3DP sand printers next, to achieve the monthly production capacity of nearly 100 tons, the annual output value of nearly 100 million yuan of the goal. "Nowadays, we can produce all kinds of complex structures, the efficiency has been improved by two times, and the cost has been reduced by half. At the same time, because the delivery cycle has been significantly shortened, the profitability of the product has also been greatly improved, we get a real benefit." In many traditional casting enterprises are still due to high energy consumption, high pollution, product precision can not meet the requirements and face the transition dilemma, Xinxin casting has been riding on the 3D printing green casting of the express car successfully realized the breakthrough.

Xin Xin casting responsible person Tan Dawei said, now more orders to do over, two 3DP sand printer 24 hours on continuous operation, the current monthly printing capacity of 20 tons of sand has been far from meeting the huge market demand. Xinxin Casting will introduce more 3DP sand printers next, to achieve the monthly production capacity of nearly 100 tons, the annual output value of nearly 100 million yuan of the goal. "Nowadays, we can produce all kinds of complex structures, the efficiency has been improved by two times, and the cost has been reduced by half. At the same time, because the delivery cycle has been significantly shortened, the profitability of the product has also been greatly improved, we get a real benefit." In many traditional casting enterprises are still due to high energy consumption, high pollution, product precision can not meet the requirements and face the transition dilemma, Xinxin casting has been riding on the 3D printing green casting of the express car successfully realized the breakthrough.

In summary, 3DP sand printing technology for sand performance, processing speed, molding size and other optimization to enhance the obvious advantages, has been maturely applied to the casting production, especially for new product development, complex products and small batch product production. With the progress of the market and the gradual increase in the speed and quality of new product development requirements, I believe that in the next few years, in the face of hundreds of billions of dollars of sand casting market, 3DP sand printing will occupy an increasing share to help China's foundry high-quality development.

[About Ryuen Molding

Longyuan AFS Co., Ltd. is a subsidiary of 3D Printing Technology, Inc. and is one of the earliest enterprises in China to realize the industrialization and servicing of industrial 3D printing, and is a national high-tech enterprise, Zhongguancun high-tech enterprise, Haidian District innovation enterprise, and Beijing Municipal Innovation Enterprise. In 1994, it developed the first commercialized industrial 3D printing equipment with independent intellectual property rights in China - Selective Area Laser Powder Sintering Rapid Prototyping Machine, and is one of the earliest enterprises in China to realize the industrialization and servicing of industrial 3D printing, and it is a National High-tech Enterprise, a High-tech Enterprise in Zhongguancun, an Innovative Enterprise in Haidian District, a Specialized Specialty Enterprise in Beijing, and an Intelligent Manufacturing Key Technology and Equipment Supplier.

Lonmold focuses on 3D printing equipment and manufacturing services, the company has nearly 30 years of experience in 3D printing services, through the research institute, postdoctoral workstations, engineering technology centers "trinity" synergistic innovation system, to provide a solid technical guarantee. Through the self-developed SLS selective laser sintering, SLM selective laser melting, 3DP sand printing, BJ inkjet metal printing, DED directional energy deposition and other series of intelligent equipment, and through the distribution of the country's manufacturing centers to provide users with sand printing rapid casting, wax printing precision casting, finished parts rapid prototyping, gradient metal 3D printing and other rapid manufacturing services. More than 1,000 equipment and processing service users are located in the fields of aerospace, automobile, motorcycle, rail transportation, ship pump valve, machinery manufacturing, art casting, metal processing and so on.