In today's industrial manufacturing field, technological innovation is driving industrial upgrading at an unprecedented rate. Among them, binder jetting (BJ) technology, due to its advantages of moldless manufacturing, high efficiency, low cost, and large-size parts manufacturing, is changing the traditional production mode, and showing great potential for batch industrialization application, becoming a new quality of productivity empowering the traditional industry.

In recent years, BJ technology has grown rapidly with the enrichment of material systems and breakthroughs in technological processes. According to SmarTech's prediction, by 2030, the global output value of BJ technology can reach 54 billion U.S. dollars (about 350 billion yuan).BJ binder jet is a 3D printing technology based on the powder bed process and inkjet principle, and the printed prototype parts (green blanks) are used to complete binder removal and densification of the blanks by using the degreasing and sintering process of the MIM (metal injection molding) technology to obtain the final part. As a high-efficiency, low-cost 3D printing technology, BJ technology combines the freedom and efficiency advantages of 3D printing and is also compatible with the standardized material system of powder metallurgy. Thus, it can play an important role in enhancing the manufacturing capability of traditional powder metallurgy, reducing costs, accelerating the R&D cycle, and realizing the manufacturing of complex structures and large-size products.

Image from: Colibrium Additive / GKN Additive

International manufacturers are optimistic about the market potential of BJ technology and have entered the market.GE General Electric has been laying out BJ technology since 2016, after its Colibrium Additive launched the Series 3 metal binder jetting system. It cooperates with automobile manufacturers to produce lightweight and high-performance automotive parts and enhance the performance of the entire vehicle.HP HP launched HP Metal Jet technology in 2018 based on its thermal inkjet (TIJ) expertise and launched HP Metal Jet S100 metal printing solution four years later.GKN Additive adopts HP Metal Jet technology for automotive and industrial parts mass production, and MIM industry leader Parmatech uses HP Metal Jet technology for the manufacture of complex shaped precision surgical tools.

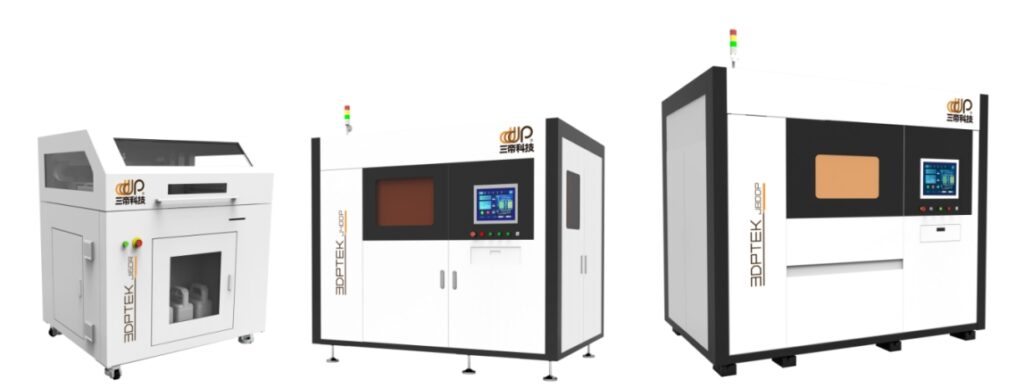

Figure: SANDY TECHNOLOGY BJ Metal/Ceramic Printer 3DPTEK-J160R, 3DPTEK-J400P/800P

As a large manufacturing country, China's market demand for BJ technology is more urgent. The leading domestic 3D printing equipment and rapid manufacturing service provider Beijing SANDI Technology Co., Ltd. independently masters the key technologies of BJ technology equipment, materials, processes, etc., and has mature technology and experience in small particle size powder placement, powder bed densification enhancement, high dimensional accuracy control, binder material system development, and degreasing sintering process. The company's self-developed 3DPTEK-J160R/J400P/J800P serialized binder jet printing equipment and its molding process integrates a precise feeding system, a high density powder laying system and a high-precision inkjet printing control system, which solves the key common technologies of small particle size and low mobility powder laying and molding density and breaks through the key technologies of high-resolution and high-precision inkjet control, and can realize 800-1200dpi high-resolution printing and molding, molding accuracy is better than ±0.1mm, molding efficiency up to 3600cc/h, the relevant technical indicators have reached the international advanced level.

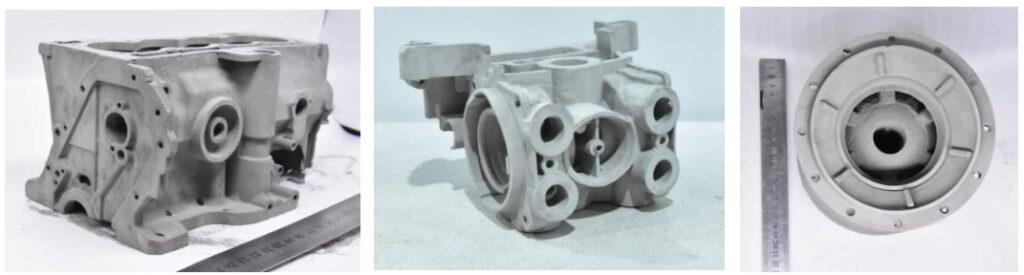

Figure: BJ metal sample

SANDI Technology has gradually formed a sound binder material molding process system in years of BJ technology research. Based on more than 20 kinds of process formulas formed by two major types of water-based environmentally friendly binder and solvent-based high-efficiency binder, we have carried out systematic research and analysis on the physical and chemical properties of the binder and the interaction between the binder and the powder, and developed corresponding molding processes and post-processing processes such as degreasing and sintering, which have realized a complete and complete molding process applicable to stainless steel, tool steel, titanium alloys, copper alloys, high-temperature alloys, hard alloys and other metal materials, silicone carbide ( SiC) and other ceramic materials, as well as PMX crystalline wax, inorganic salts, food, pharmaceuticals, polymer composites and other non-metallic materials molding process. Meanwhile, through the systematic research on high density degreasing and sintering molding process, we have realized the shape and property control of metal and ceramic products in the process of degreasing and sintering, and realized the precise control of the quality of the finished products after degreasing and sintering, and the performance of the products is better than the mechanical properties of the MIM international material standard.

Figure: BJ ceramic sample

At the same time of realizing independent technological innovation, SANDI Technology gradually completes the construction of BJ standard manufacturing process, and establishes distributed printing service centers across the country to develop product manufacturing process based on BJ technology for customers, and promotes its application to the market. In addition, the company jointly with the Shenzhen Vocational and Technical University to build a joint laboratory of additive manufacturing technology, combined with Shenzhen Tsinghua University Research Institute, Shanghai Jiao Tong University, University of Science and Technology in Beijing and other research institutes and related teams to jointly carry out binder jet molding and other materials, process and application of basic technology research, and to promote the industrialization and application of the industrial molds, cutting tools, 3C electronic products, and complex, shaped and large-size ceramic products and other fields. Industrialization application.

In the field of 3C electronics, the market demand for increasingly diversified, complex and refined products has posed challenges to manufacturing technology, and traditional manufacturing technology has many limitations such as high manufacturing difficulty, low yield, high cost, etc., especially titanium alloys and other difficult-to-machine lightweight materials are even more difficult to realize. SANDI Technology has successfully broken through the traditional titanium alloy forming manufacturing technology barriers, based on BJ technology to achieve the rapid prototyping manufacturing of titanium alloy and other active metals, to realize the complex structure of 3C electronic product parts and components fast near-net shaping at the same time to simplify the manufacturing process and reduce the production and manufacturing costs.

Chart:Based on SANTI TechnologyautonomyBJskillfabrication(used form a nominal expression)Typical 3CProduct ComponentsMinimum structural scale 0.4mm, sintered densities better than 99%

In the field of food and drugs, in response to the growing demand for diversified, personalized and precise dietary markets, SANDI Technology, in conjunction with the Institute of Agricultural Products Processing of the Chinese Academy of Agricultural Sciences, carries out research on the adaptability of technology and equipment and equipment integration based on the self-developed BJ equipment, develops easy-to-swallow food made of food hydrogel and special shaped food made of food-based particles and carries out comprehensive evaluations of its safety and reliability. Comprehensive evaluation, and ultimately realize the industrialization demonstration application of personalized food additive manufacturing and intelligent processing equipment.

In the field of molds, for the problem of the difficulty of manufacturing molds with complex surfaces and fine texture structures, based on SANDI's BJ technology, it can realize the manufacturing of metal molds with high complexity and fineness in the scale range of 300mm×200mm×150mm, with the minimum texture expression scale of about 0.26-0.3mm, and at the same time, it breaks through the technology of sintering and densification of large-size atypical structural metal parts to realize At the same time, we have broken through the sintering densification technology for large-size non-typical structural metal parts, and realized the shape-controlled sintering with sintering performance meeting the requirements of practical applications.

With the continuous progress and innovation of technology, BJ technology is expected to play a more critical role in the future of industrial manufacturing, and its positive impact on manufacturing costs, efficiency and quality will certainly further promote this technology in 3C electronics, molds, automobiles, hardware, tools, cutting tools, medical equipment, sports equipment and other industries to form a hundred billion scale of industrialized applications.

[___About SANDI Technology]

3D Printing Technology, Inc. is a 3D printing equipment and rapid manufacturing service provider, a national "specialization, specialization and innovation" small giant enterprise, the Ministry of Industry and Information Technology additive manufacturing typical application scenarios supplier. At the same time has laser and binder jet 3D printing equipment and materials technology and application process, business covers 3D printing equipment, raw materials research and development and production, metal parts rapid manufacturing services, 3D printing process technology support services, etc., to establish a complete 3D printing additive manufacturing industry chain, widely used in aerospace, ship pumps and valves, automotive, energy power, industrial machinery, rail transportation, 3C, electronics, education and research, sculpture, culture and creativity. electronics, education and scientific research, sculpture and cultural creation, rehabilitation and medical industries.