Investment casting, i.e. lost wax casting technology, occupies an important position in modern industrial manufacturing. With the unique advantage of less cutting or even no cutting, this technology is widely used in the precision casting of all kinds of alloys, especially in the dimensional accuracy and surface quality. From precision instruments to complex large-scale mechanical components, investment casting technology can meet the demand for high-precision, high-quality castings in various industries, and become the key to improve product quality and production efficiency. Its core competitiveness lies in its high-precision wax mold making capability and highly customized solutions. Through precise mold design and production process, it ensures the dimensional accuracy and shape consistency of the wax molds, providing a solid guarantee for the subsequent casting process.

Investment casting technologyNot only is it suitable for a wide range of casting metals, but it also demonstrates strong customization capabilities due to the flexibility of its wax modeling process, which further broadens the range of applications. InAerospace, manufacturing lightweight, high-precision parts to safeguard aircraft safety and performance; in theAutomotiveIn the field of industrial automation, it is used to manufacture key components of robots, precision instruments and equipment to ensure their performance and stability. In addition, the technology is also widely used in machinery manufacturing, energy power, rail transportation, sculpture, culture and creativity and other fields, for complex structures, large-size thin-walled products such as manufacturing.

However, this traditional process also faces the challenges of low productivity, high costs and high technical thresholds, especially in industries that require rapid market response or where cost control is particularly stringent.

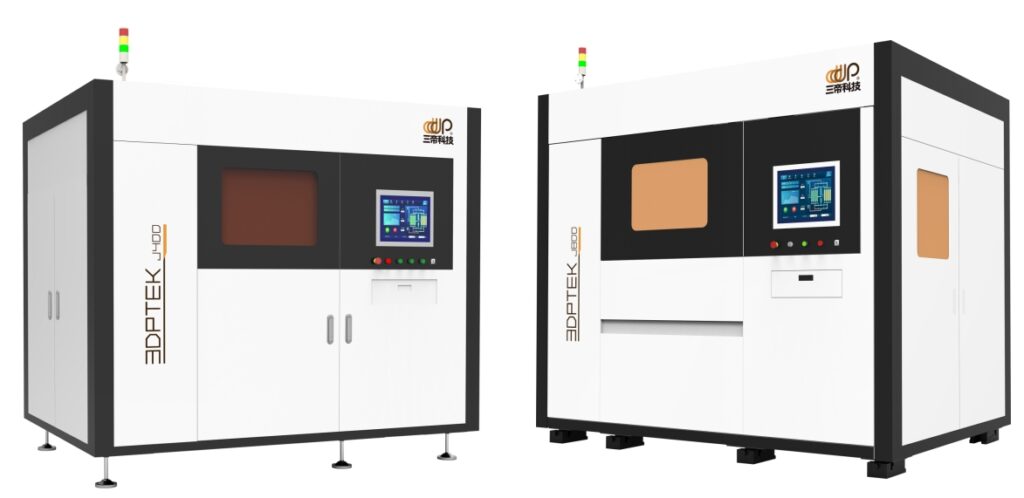

Figure: SANDY TECHNOLOGY 3DP WAX PRINTER 3DPTEK-J400/J800

(hereinafter referred to as “3DPTEK”), a leading provider of 3D printing equipment and rapid manufacturing services in China, has independently developed and launched a series of 3DP wax printing equipment and material process, which is specially designed for industrial investment casting, and can realize low-cost and high-efficiency precision casting.

Based on the BJ binder jet molding technology, 3DP wax printing from 3DPTEK TECHNOLOGY can achieve processing speeds far exceeding those of laser molding, significantly shortening the processing cycle time and reducing material costs. At the same time, production efficiency is further enhanced by eliminating the need for mold opening and support structures. As a cold process molding technology, warping and deformation are effectively avoided during the molding process, reducing the complexity and time cost of subsequent processing.

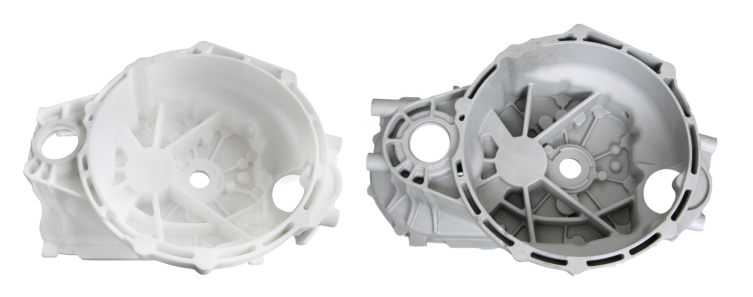

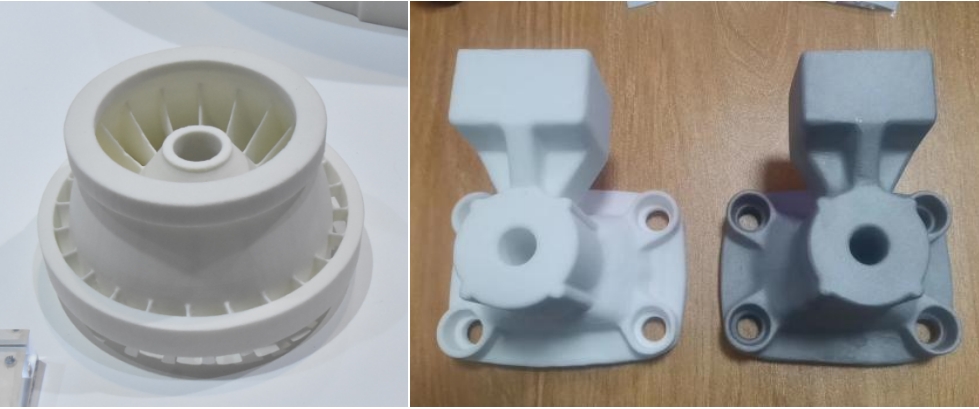

Figure: 3DP Wax Mold Printing Precision Casting

3DPTEK 3DP wax printer 3DPTEK-J400/J800 has a molding accuracy of up to 800DPI and a minimum wall thickness of up to 1.5mm.The self-developed PMX crystalline wax material has a strong vanishing property and a very low ash content, which is extremely beneficial to the pouring process, and is able to significantly reduce the casting defects and enhance the yield rate, while at the same time reducing the pollution and realizing the green casting. It has already realized its application in the investment casting industry and shows great potential.

In the country vigorously advocate the casting industry to move towards digitalization, intelligence, green development, 3DP wax precision casting process is undoubtedly the emergence of those who are looking for technological innovation, transformation and upgrading of the traditional precision casting enterprises to provide a direction.

[About SANDI TECHNOLOGY

3D Printing Technology, Inc. is a 3D printing equipment and rapid manufacturing service provider, a national "specialization, specialization and innovation" small giant enterprise, the Ministry of Industry and Information Technology additive manufacturing typical application scenarios supplier. At the same time has laser and binder jet 3D printing equipment and materials technology and application process, business covers 3D printing equipment, raw materials research and development and production, metal parts rapid manufacturing services, 3D printing process technology support services, etc., to establish a complete 3D printing additive manufacturing industry chain, widely used in aerospace, ship pumps and valves, automotive, energy power, industrial machinery, rail transportation, 3C, electronics, education and research, sculpture, culture and creativity. electronics, education and scientific research, sculpture and cultural creation, rehabilitation and medical industries.