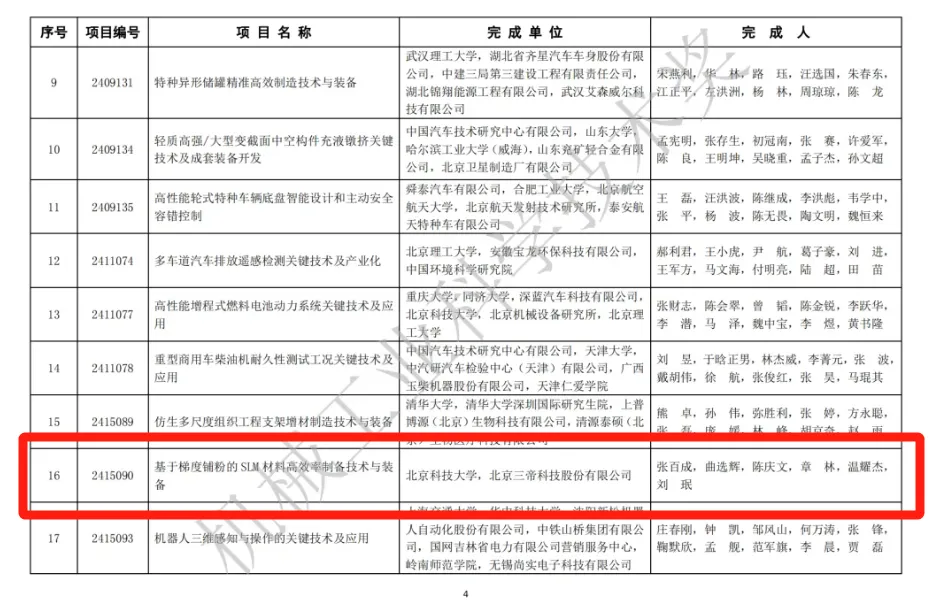

Recently, the China Machinery Industry Federation (CMIF) and the Chinese Society of Mechanical Engineering (CSME) announced the2024 Machinery Industry Science and Technology Award WinnersThe University of Science and Technology Beijing, together with Beijing SANDI Technology Co. (hereinafter referred to as "SANDI"), jointly declared by the University of Science and Technology Beijing and Beijing SANDI Technology Co.High Efficiency Preparation Technology and Equipment for SLM Materials Based on Gradient Powder SpreadingProject, honored withSecond Prize of "Machinery Industry Science and Technology Award"The members of the project team areZhang Baicheng, Qu Xuanhui, Chen Qingwen, Zhang Lin, Wen Yaojie, Liu MinThe

The Machinery Industry Science and Technology Award is a comprehensive science and technology award in the national machinery industry jointly established by the China Machinery Industry Federation and the Chinese Society of Mechanical Engineering and approved by the Ministry of Science and Technology of the People's Republic of China.In the year of 2024, a total of 430 projects were awarded with "Machinery Industry Science and Technology Award", among which, 5 projects were awarded with the Grand Prize, 40 projects with the First Prize, 197 projects with the Second Prize and 188 projects with the Third Prize. This award is a full affirmation and recognition of the company's scientific and technological innovation ability.

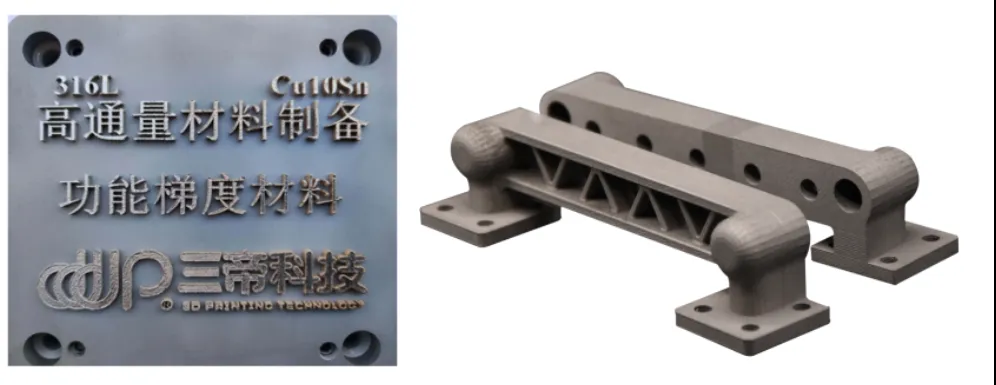

Figure: Gradient Metal Parts 316L-CuSn10; 1.2709-316L

The award-winning program presents "High-efficiency preparation of SLM materials based on gradient spreading of powder"New ideas, developedHigh-efficiency preparation of multi-phase continuous gradient SLM materials, realizing stable layup of two/multi-phase full-scale continuous gradient powder layers, which helps to enhance the technological level of efficient material preparation in China.

As a leading domestic3D Printing Equipment and Additive Manufacturing Service ProviderSANDI Technology has independently developed the gradient metalAFS-M120X(T)Multi-material gradient metal with increase or decrease in materialAFS-M300XASetc.; in which multi-material increase/decrease material gradient metalAFS-M300XASsuitable forResearch and development of properties of composite metal materials with gradients of up to four materials, continuous gradient changes in the horizontal direction, and material composition switching or gradient changes in the vertical direction.It lowers the threshold of gradient composite material preparation process, reduces the loss of powder raw materials and improves the efficiency of research and development. It has a broad application prospect in the development of new materials in high throughput material preparation, aerospace, automotive, medical, mold processing and other fields. At present, SANDI has cooperated with many research institutes such as University of Science and Technology Beijing, Shandong University of Science and Technology, Lanzhou University of Science and Technology, Huazhong University of Science and Technology, Beijing University of Aeronautics and Astronautics, Beijing Iron and Steel Research Institute, Shenyang Institute of Automation, etc., to continuously provide advanced, reliable and practical solutions for gradient functional metal materials.

[About SANDI TECHNOLOGY

3D Printing Technology, Inc. is a 3D printing equipment and rapid manufacturing service provider, a national "specialization, specialization and innovation" small giant enterprise, the Ministry of Industry and Information Technology additive manufacturing typical application scenarios supplier. At the same time has laser and binder jet 3D printing equipment and materials technology and application process, business covers 3D printing equipment, raw materials research and development and production, metal parts rapid manufacturing services, 3D printing process technology support services, etc., to establish a complete 3D printing additive manufacturing industry chain, widely used in aerospace, ship pumps and valves, automotive, energy power, industrial machinery, rail transportation, 3C, electronics, education and research, sculpture, culture and creativity. electronics, education and scientific research, sculpture and cultural creation, rehabilitation and medical industries.