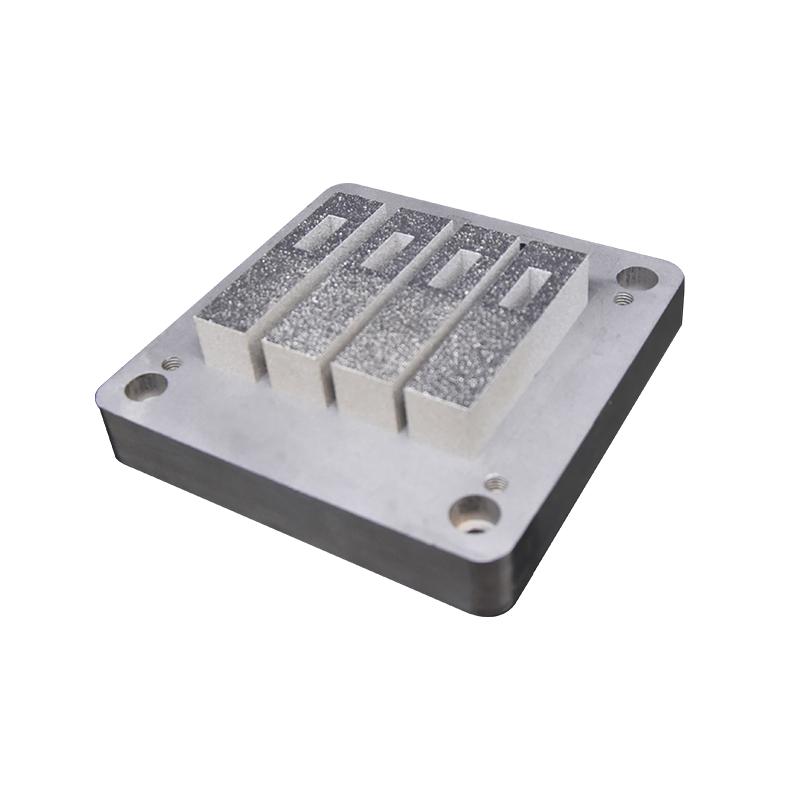

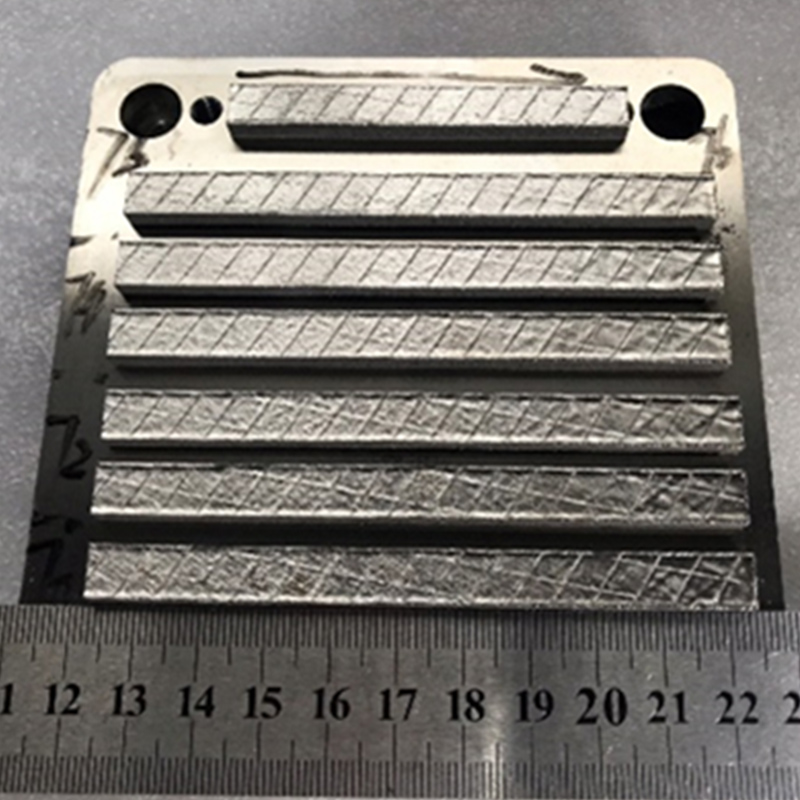

Based on the principle of high-performance continuous gradient alloy near-net forming technology, the company has developed and launched the selective zone laser melting gradient metal printing equipment AFS-M120XT, which can realize the precise control of material gradient in the horizontal/vertical direction, and with the vertical multi-powder spreader interlayer gradient supply/spreading system to complete the alternate spreading of heterogeneous powders, and can realize the multi-dimensional additive manufacturing of more than three-gradient materials.

Horizontal/vertical gradient function

- Particularly suitable for research and development of the properties of composite metallic materials.

- The powder supply system can realize the continuous gradient accurate powder supply of two or more kinds of metal materials.

- With horizontal/vertical gradient change direction, it reduces process complexity, saves powder raw materials and improves R&D efficiency.

- Gradient change of two materials in the horizontal direction can be realized, and two-phase full-scale change of gradient materials can be prepared.

- High molding accuracy, macroscopic marking of gradient proportions in the material of manufacture.

- Gradient alloy manufacturing with customized ratio changes can be achieved by changing the powder storage mechanism.