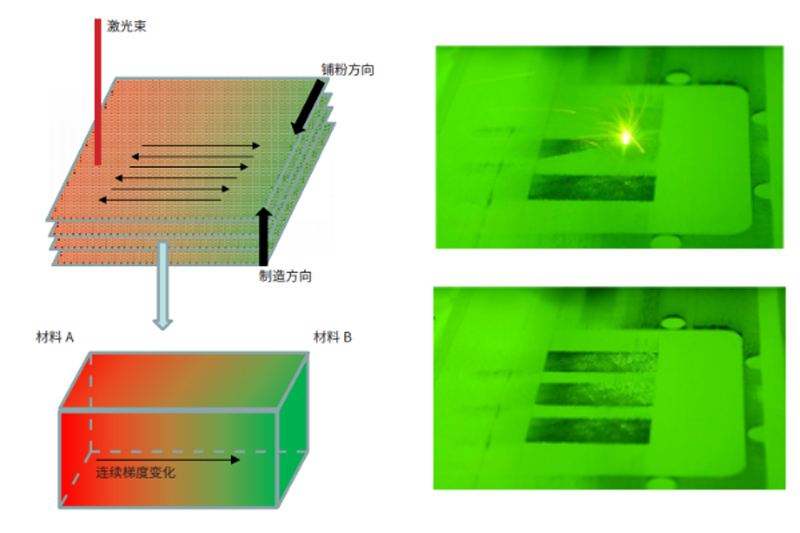

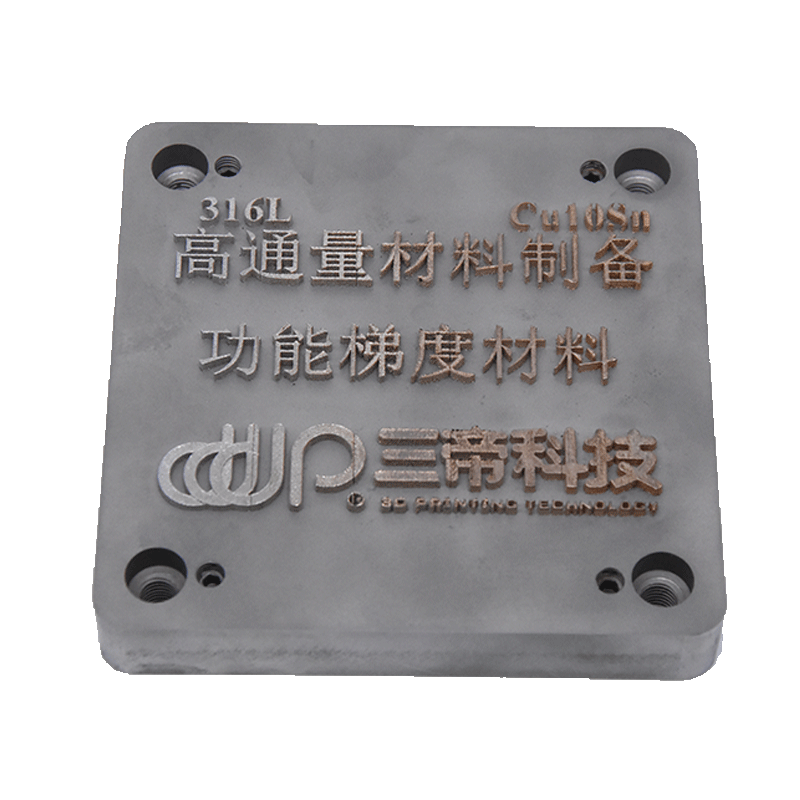

Based on the principle of high-performance continuous gradient alloy near-net forming technology, the company has developed and launched the selective laser melting gradient metal printing equipment AFS-M120X, which can realize continuous gradient change of two (or more) powder materials along the X-axis direction, and keep unchanged in the Y-axis direction and Z-axis direction, and obtain the continuous and dense gradient metal materials through selective melting by the laser, and also realize customized gradient materials by changing the powder storage mechanism. Customized gradient alloys can also be manufactured by changing the powder storage mechanism.

Horizontal gradient function

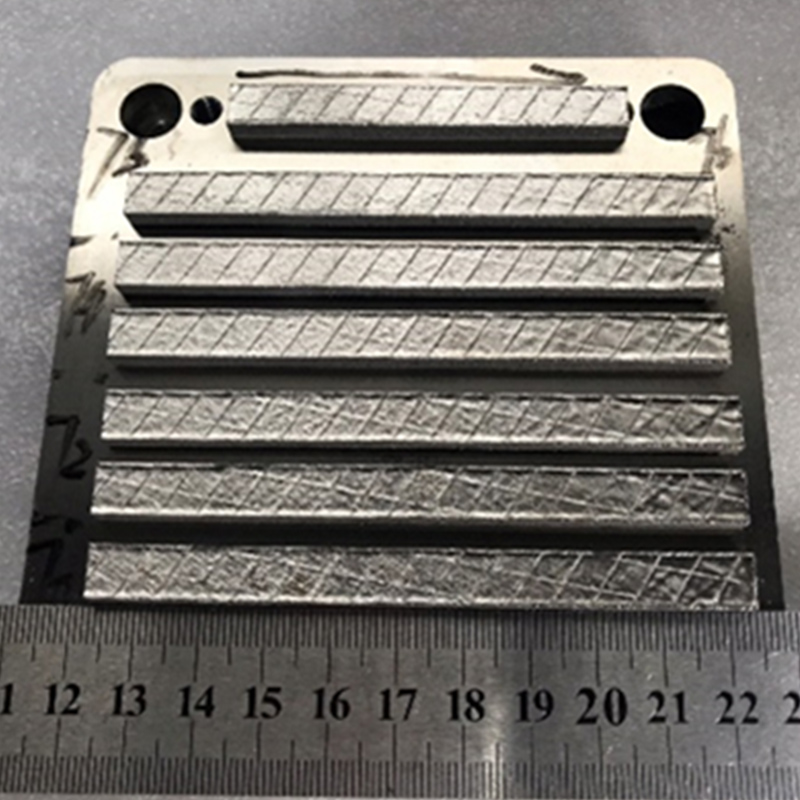

- Particularly suitable for research and development of the properties of composite metallic materials.

- The powder supply system can realize the continuous gradient accurate powder supply of two or more kinds of metal materials.

- With horizontal gradient change direction, it reduces process complexity, saves powder raw materials and improves R&D efficiency.

- Gradient change of two materials in the horizontal direction can be realized, and two-phase full-scale change of gradient materials can be prepared.

- High molding accuracy, macroscopic marking of gradient proportions in the material of manufacture.

- Gradient alloy manufacturing with customized ratio changes can be achieved by changing the powder storage mechanism.