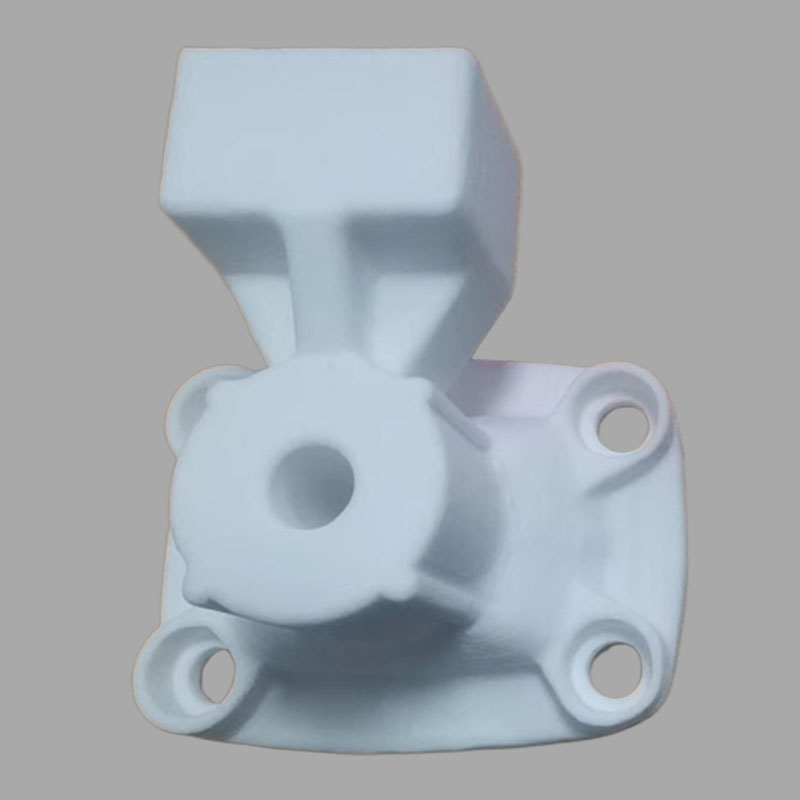

The company's self-developed 3DP wax 3DP printer, 3DPTEK-J400, can be realized:

Based on the BJ binder jet molding technology, 3DP wax printing from 3DPTEK TECHNOLOGY can achieve processing speeds far exceeding those of laser molding, significantly shortening the processing cycle time and reducing material costs. At the same time, production efficiency is further enhanced by eliminating the need for mold opening and support structures. As a cold process molding technology, warping and deformation are effectively avoided during the molding process, reducing the complexity and time cost of subsequent processing.

The self-developed PMX crystalline wax material has strong disappearance and very low ash content, which is extremely beneficial to the pouring process, and can significantly reduce casting defects and improve the yield rate, as well as reduce pollution and realize green casting. It has already realized its application in the investment casting industry and shows great potential.

| Item | Performance Parameters |

| Equipment body size (L×W×H) | 2470×1730×2400 mm |

| Molding cylinder size (L×W×H) | 400×400×310 mm |

| Molding size (L×W×H) | 380×380×300 mm |

| Printhead Print Resolution | 400dpi/800dpi |

| Maximum molding speed | 2.8L/h |

| Molding thickness | 0.1-0.2mm |

| Post-treatment process | Curing-impregnation |

| Number of nozzles | 3/6 |

| Molding materials | PMX Crystalline Wax |