July 4, the twenty-second China International Foundry Expo, the seventeenth China International Die Casting Industry Exhibition, the international non-ferrous and special casting exhibition in Shanghai - National Convention and Exhibition Center grand opening, attracted more than 1500 exhibitors from 26 countries and regions around the world as well as tens of thousands of professional visitors to participate in the grand event, for the traditional foundry industry to "new" Improve the "quality", to realize the leapfrog development to accumulate kinetic energy.

At the China Foundry Association's annual meeting on July 3 "Casting Frontier Technology"In the forum, Dr. Zong Guisheng, Chairman of Beijing SANDI Technology Co., Ltd. made a speech onAdvances in high-efficiency and low-cost metal additive manufacturing technologies and applicationsDr. Zong Guisheng, the keynote report, shared the significant progress of metal additive manufacturing in improving manufacturing efficiency and reducing manufacturing costs, as well as the industrialization of 3D casting and typical application cases. Dr. Zong Guisheng said that the development of metal additive manufacturing technology for nearly forty years has been centered on the core elements of manufacturing to improve efficiency and reduce costs. From single laser point scanning to multi-point laser scanning, and then to the surface laser printing, from a single machine binder line scanning printing sand mold service to "multi-machine + casting + machining" fast delivery, additive manufacturing manufacturing efficiency has been hundreds of times higher, the cost has also dropped dramatically, to reach the level of production factories can be accommodated, the application of the growing popularity has become a new quality to promote the high-quality development of the foundry industry. The application is becoming more and more popular, and has become a new quality productivity to promote the high-quality development of the casting industry.

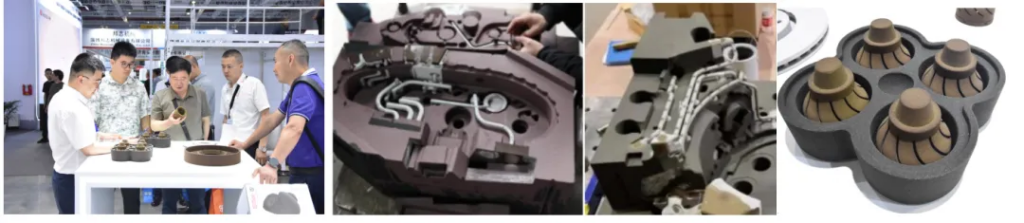

Based on the independent core technology of 3D printing equipment, materials and process, SANDY actively promotes the industrialized scale application of 3D printing, and empowers casting (3D casting) with 3D printing: through the merger and acquisition of foundries, we have opened up the "3D printing + casting" process, which is not only independently controllable in terms of core equipment, but also can be customized according to the user's requirements for casting and the corresponding binder. Corresponding binder, at the same time can provide the downstream foundry to verify the success of the process package and on-site operation training, through the whole industry chain overall solution, to really help the foundry to apply 3D printing technology to manufacture satisfactory products, to help its transformation and upgrading, and to realize the green, intelligent, high-end casting.

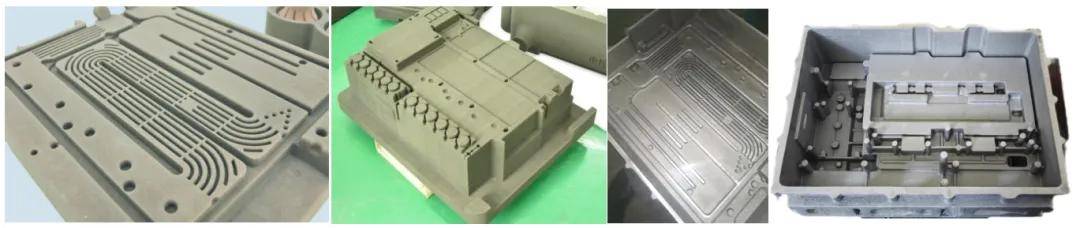

The company's unique "SLS Coated Sand Molding Process + 3DP Resin Sand Molding Process"Combined sand mold manufacturing, can achieve complex structural components (large size, thin-walled, fine piping, etc.) of high-precision and high-strength integrated casting molding, the process has been selected as the Ministry of Industry and Information Technology additive manufacturing typical application scenarios.

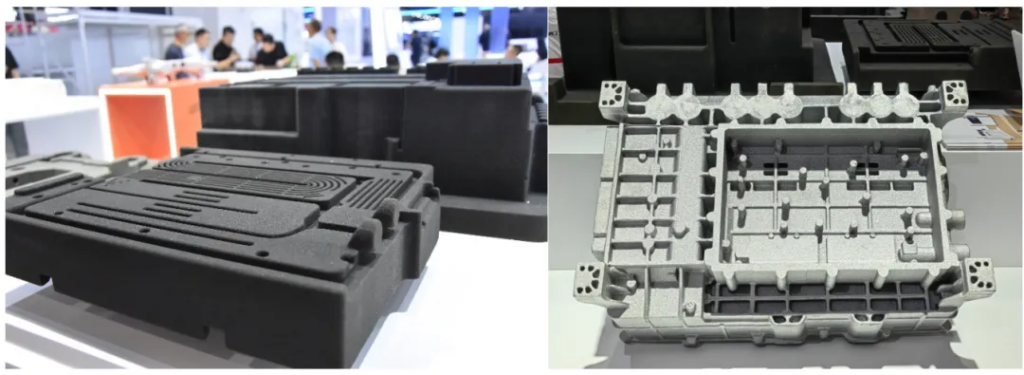

3DP sand casting processThe company is free from opening molds, and can realize high precision and high strength integrated casting molding of large-size, thin-walled, fine piping, and complex structural parts. Short production cycle, small batch production advantage is obvious, design flexibility, can be modified in time, reduce production costs. Improve the production environment, reduce labor intensity, save labor costs, greener, smarter.

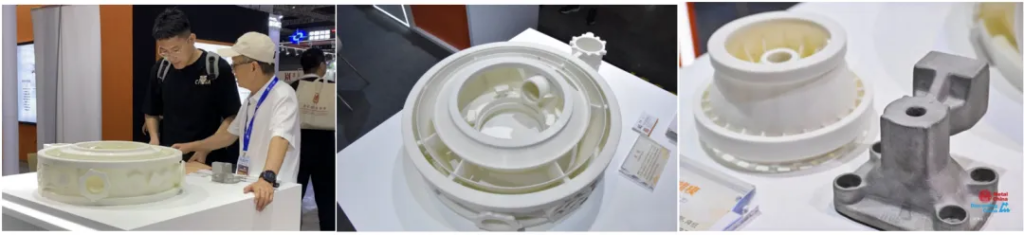

SLS wax casting processThe company is free from opening molds, and can realize high-precision and high-strength integrated precision casting molding of complex structures, thin-walled and large-sized products. Short production cycle, small batch production advantage is obvious.PMX crystalline wax fine casting processIt can significantly shorten the processing cycle, reduce production cost, no need to open the mold and add support, no warping and deformation in the molding process, reduce post-treatment steps, and high molding accuracy. The company's own research and development of the material disappearing strong, low ash, can reduce casting defects, improve the yield, has been successfully applied in the foundry industry.

3D casting technology is gradually showing its unique application value in various fields. In the aerospace field, 3D casting technology is used to manufacture engine parts, spacecraft structural parts, power units and other important parts, can effectively solve the oversized, multi-dimensional surfaces, complex structure of the workpiece molding problems in small quantities of large-size mold manufacturing as well as special industry mold iterative upgrading of research and development on the traditional manufacturing process can not be compared with the advantages. In the field of energy and power, 3D casting technology is used in the manufacture of large-size pressure-resistant complex cavity structure, large-size thin-walled lightweight parts and components.

A customer giant, large plane, thin-walled structural components, the use of traditional welding and casting process is difficult to meet the requirements, the use of three emperor technology 3D casting process, 45 days to deliver two finished products, finished product size of 1800mm × 2000mm, wall thickness of 5.5mm.

A customer's giant aluminum alloy casting weighing 1.25 tons, with a diameter of 900mm at the lower end, 1200mm at the upper end, and a height of 1850mm, had high costs and long lead times in traditional manufacturing methods, and was unable to achieve the required complex structure. The delivery was completed in only 15 days by using 3D casting process of SANDI Technology, which saved a lot of time and cost for the customer.

At present, the 3D casting overall solution of SANDI Technology has been maturely applied commercially in casting production. The foundry that took the lead in introducing 3D casting has established green, flexible and high-end fast casting capability, realized the doubling of productivity, capacity and revenue, and successfully transformed into a green fast casting demonstration factory.

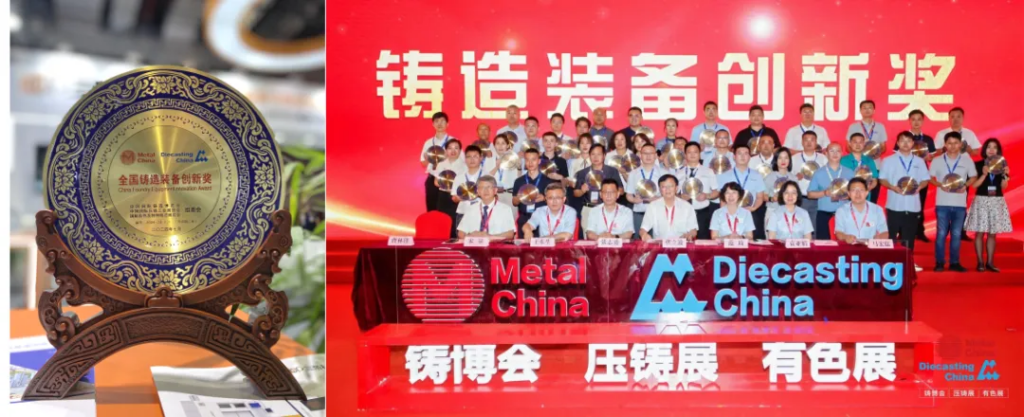

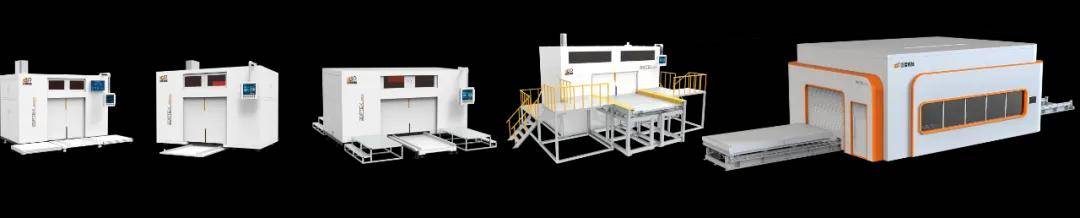

In this casting expo, the 4-meter large size 3DP sand printer independently developed by SANDI Technology3DPTEK-J4000Won the "National Foundry Equipment Innovation Award", "millions of subsidies, booking reduction" new product promotional activities are also in full swing, during the exhibition, booking 3DPTEK-J4000 and above size models, immediate reduction of 100,000, a limited number of 10, want to book as soon as possible! Book now! The final interpretation of the rules of this promotion belongs to Beijing SANDI Technology Co.

The equipment breaks through the traditional processing size limitations, the maximum molding 4 meters of sand. And creative use of no sand box flexible area molding technology, breaking the phenomenon that the larger the size of the equipment molding, the more expensive the equipment, 4 meters of equipment for only 2 meters of equipment prices, with lower unit costs and shorter delivery time, cost-effective realization of oversized sand manufacturing, and can be customized according to user needs on-demand expansion of the printing platform to meet the production needs of the 10-meter + level (6 m/8 m/ 10m equipment has been in the synchronization of accepting reservations). At the same time, the company provides open source material process, can be adjusted for the user on demand; supporting high-performance resin binder, curing agent, cleaning agent, to ensure the molding quality and stability.

This year's show will last until July 7, Shanghai-National Convention and Exhibition Center, theSANDY TECHNOLOGY Booth: Hall 4.1H, 4F05We welcome you to come and share with us!

SANDY TECHNOLOGY Booth: Hall 4.1H, 4F05

SANDY TECHNOLOGY Booth: Hall 4.1H, 4F05

The 22nd China International Foundry Expo will be held on July 4, 2024 in Shanghai - National Convention and Exhibition Center (No. 333, Songze Avenue, Qingpu District, Shanghai), Beijing SANDY Technology Co. In order to return the support of the majority of users, our company proudly launched the "million subsidies, booking discount" new promotional activities! During the exhibition period, the booking of oversized casting sand printer 3DPTEK-J4000 and above size models, 100,000 off, limited to 10, welcome inquiries and orders!

The final interpretation of the rules of this promotion belongs to Beijing SANDI Technology Co.

Ultra-large size 3D casting sand printer 3DPTEK-J4000

SANDI Technology's self-developed oversized 3DP sand printer 3DPTEK-J4000 breaks through the traditional processing size limitations, the maximum molding 4 meters of sand. The device creatively adopted the sandbox-free flexible area molding technology, breaking the phenomenon that the larger the size of the equipment molding, the more expensive the equipment. With lower unit cost and shorter delivery time, cost-effective realization of oversized sand manufacturing, and can be customized according to user needs to expand the printing platform to meet the production needs of the 10 m + level (6 m/8 m/10 m equipment has been in the synchronization of accepting reservations).

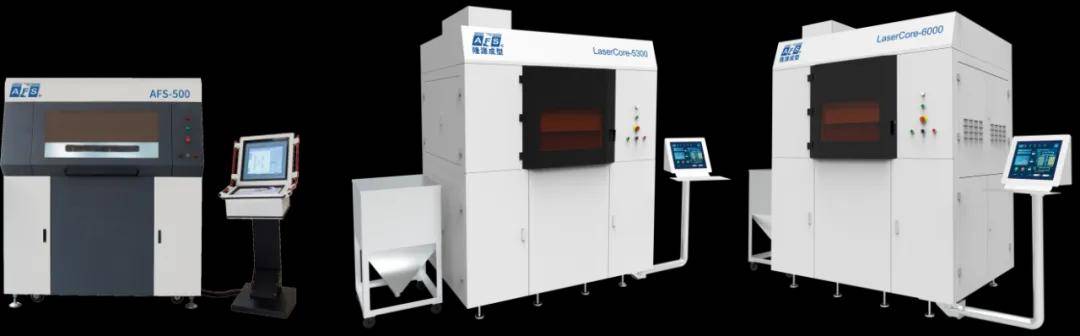

In order to meet the diversified market demands, SANDY Technology has self-developed and launched full-size 3DP casting sand printers, SLS casting sand/wax printers and PMMA wax printers, which help users maximize their productivity with lower cost per unit and shorter delivery time.Introduction of English version of sand 3D printer

Figure: 3DP Casting Sand Printer

Figure: 3DP Casting Sand Printer

Figure: SLS Casting Sand/Wax Printer

Figure: SLS Casting Sand/Wax Printer

Additive manufacturing services (3D casting)

With nearly 30 years of experience in 3D printing service and casting, based on the integrated technology process of "process design, 3D printing, casting, machining and testing", SANDI can provide high-quality R&D trial production, small-lot, multi-species, complex structure of metal products rapid manufacturing services. Through self-developed 3DP inkjet sand molding, SLS selective laser sintering, PMMA and other 3D printing equipment, the company has formed a full set of process solutions, such as 3DP sand casting, SLS sand casting, SLS wax mold fine casting, PMMA fine casting and so on. We can provide users with rapid manufacturing services for aluminum alloy, copper alloy, cast iron, cast steel, magnesium alloy, high-temperature alloy, titanium alloy and so on.

"SLS+3DP" sand composite process

The company's unique "SLS coated sand molding process + 3DP resin sand molding process" combination of sand mold manufacturing, complex structural components (large, thin-walled, small pipelines, etc.) can be realized in high-precision, high-strength integrated casting molding, the process has been selected by the Ministry of Industry and Information Technology of the typical application of additive manufacturing scenarios.

3DP sand casting process

No need to open the mold, can realize the large, thin-walled, fine pipeline, complex structure parts of the high-precision and high-strength integrated casting molding. Short production cycle, small batch production advantage is obvious, design flexibility, can be modified in time, reduce production costs. Improve the production environment, reduce labor intensity, save labor costs, greener, smarter.

SLS wax casting process

No need to open the mold, can realize the complex structure, thin-walled, large size products of high precision and high strength integrated precision casting molding. Short production cycle, small batch production advantage is obvious.

PMMA wax mold casting process

Significantly shorten the processing cycle, reduce production costs, no need to open the mold and add support, no warping and deformation in the molding process, reduce the post-treatment steps, and high molding accuracy. The company's self-developed materials with strong disappearance and low ash content can reduce casting defects and improve the yield rate, which has been successfully applied in the casting industry.

Contact: Manager Han

Contact: 13811566237

Website:www.3dptek.com

Address: Building 2, No.7 House, Jin Yi Street, Shunyi District, Beijing, China