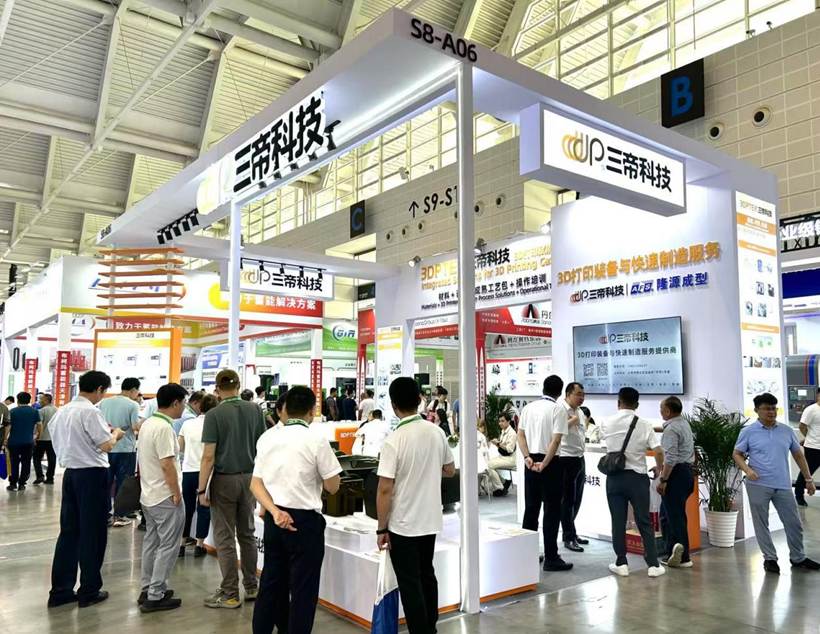

On May 20, the 23rd China International Foundry Expo (Metal China) was grandly opened at the National Convention and Exhibition Center in Tianjin, and Beijing SANDI Technology Co., Ltd. exhibited with large-size 3D casting solutions.

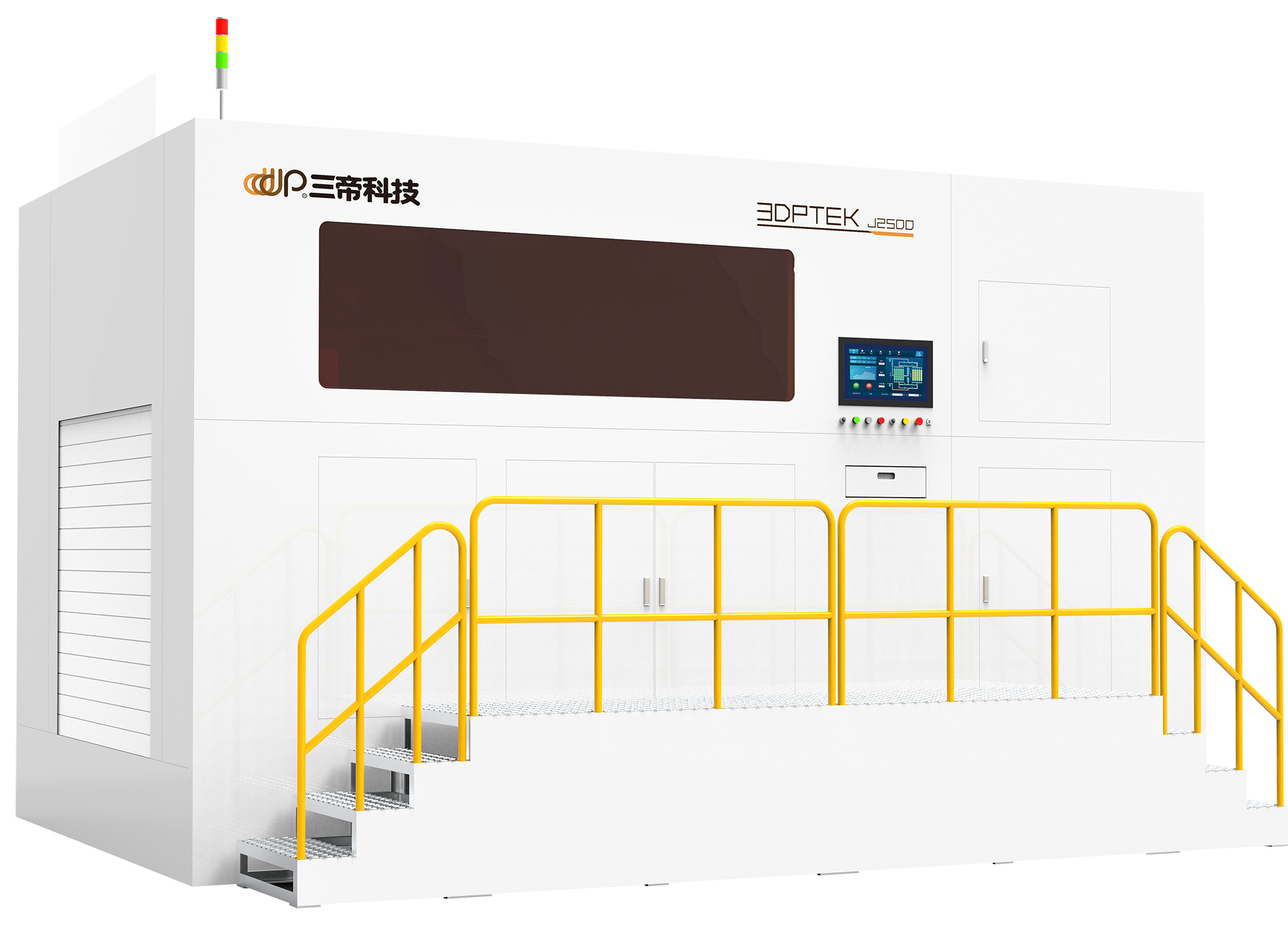

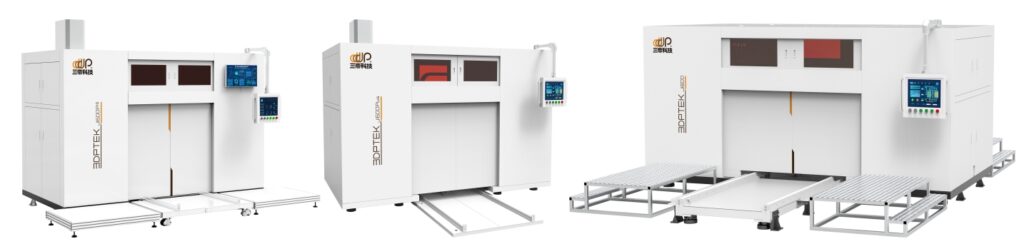

2025National Foundry Equipment Innovation Award Product: 2.5m 3DP Sand Printer 3DPTEK-J2500

The award-winning product 3DPTEK-J2500 is an industrial-grade sand printer independently developed by SANDI Technology, with a molding size of 2500×1500×1000mm and a printing accuracy of ±0.3mm, which is suitable for the needs of large castings in the fields of electric power and energy, ships, pumps and valves, and automobiles. It adopts piezoelectric inkjet technology, high-resolution inkjet system and special binder formula to realize high-precision, low-cost integrated molding of large-size complex structure castings, avoiding the loss of precision of traditional splicing process. Through digital moldless molding technology, it can reduce mold development costs and waste emissions, and help enterprises reduce costs and increase efficiency and sustainable development.

Cutting-edge casting technology: 3D printing of oversized sand molds without sandboxes

In the May 19th annual meeting of the China Foundry Association "casting cutting-edge technology" forum, Beijing Three Emperor Technology Co., Ltd. 3D equipment marketing department general manager Jiang Qingjie published "no sand box oversized 3D printing casting sand mold technology and equipment," the theme of the report, focusing on the analysis of the company in the field of ultra-large casting technology breakthroughs in the field of manufacturing.

Figure: Jiang Qingjie, general manager of 3D equipment marketing department of SANDI Technology, delivered a theme report of "sandbox-free super-large-size 3D printing casting sand mold technology and equipment".

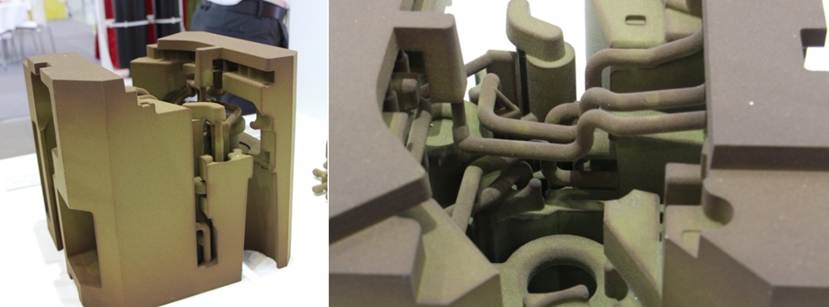

For aerospace, electric power energy, ships, pumps and valves and other fields of large castings have long faced low efficiency, high cost, inconsistent quality and other pain points, three emperor technology launched 3DPTEK-J4000 sand box without sand box large size 3D printing sand molding equipment. The equipment adopts sandless box flexible area molding technology, support local printing, the maximum molding size of 4 meters, the core advantages include:

Integrated molding of complex structures: Through high-precision nozzles and intelligent algorithms, it realizes one-time molding of thin-walled, multi-dimensional curved surfaces and complex inner cavities (such as spiral cooling water channels), breaking through the design limitations of traditional processes;

High efficiency and low cost: Compared with the traditional split casting, the production cycle is shortened by more than 50%, and the delivery time is compressed from 60 days to 15 days for a 1.25-ton aluminum alloy casting, for example;

Economy optimization: equipment costs are benchmarked against 2.5m class models, and the open source material process supports on-demand adjustment of binder and sand to further reduce overall costs.

Figure: 4-meter 3DP sand printer 3DPTEK-J4000

Equipment order hotline: 13811566237

Meanwhile, in order to meet diversified market demands, based on 30 years of experience in powder laying technology, SANDI Technology independently develops full-size 3DP casting sand and SLS casting sand/wax series printers from millimeter to meter scale, which can meet the manufacturing needs of products of different sizes and materials, and help users maximize their productivity at a lower unit cost and a shorter delivery time.

Figure: 1.6m, 1.8m 3DP casting sand printer

Figure: SLS Casting Sand/Wax Printer

Equipment order hotline: 13811566237

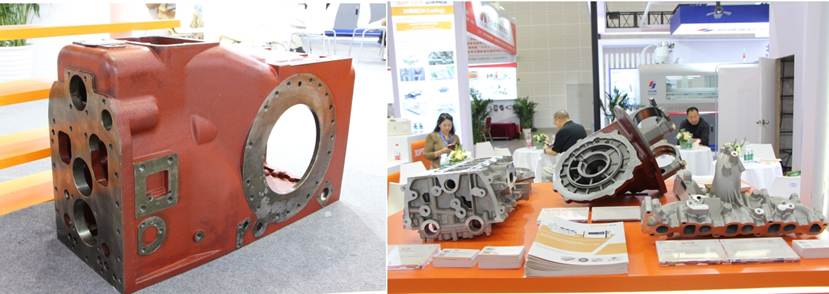

3DCasting Services

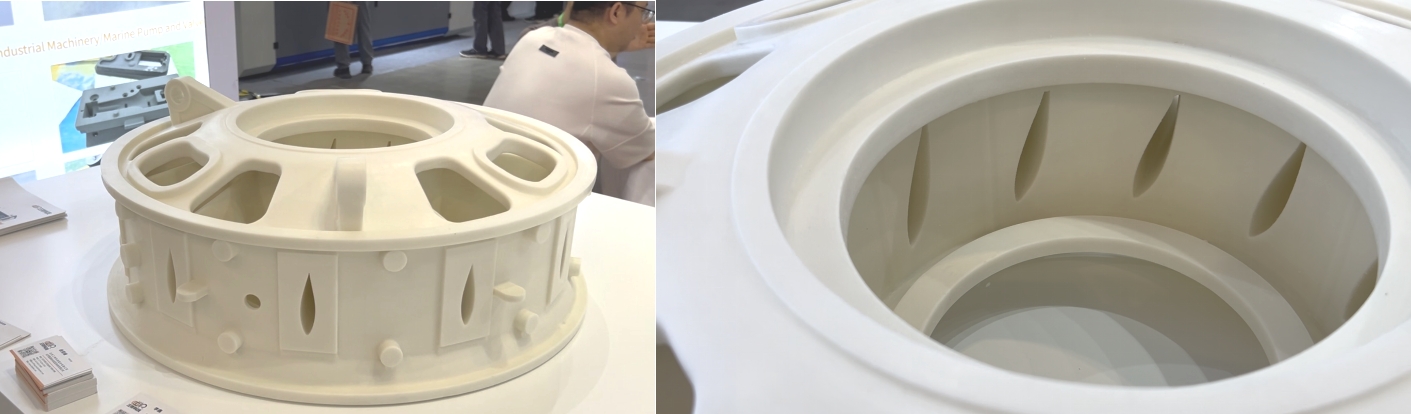

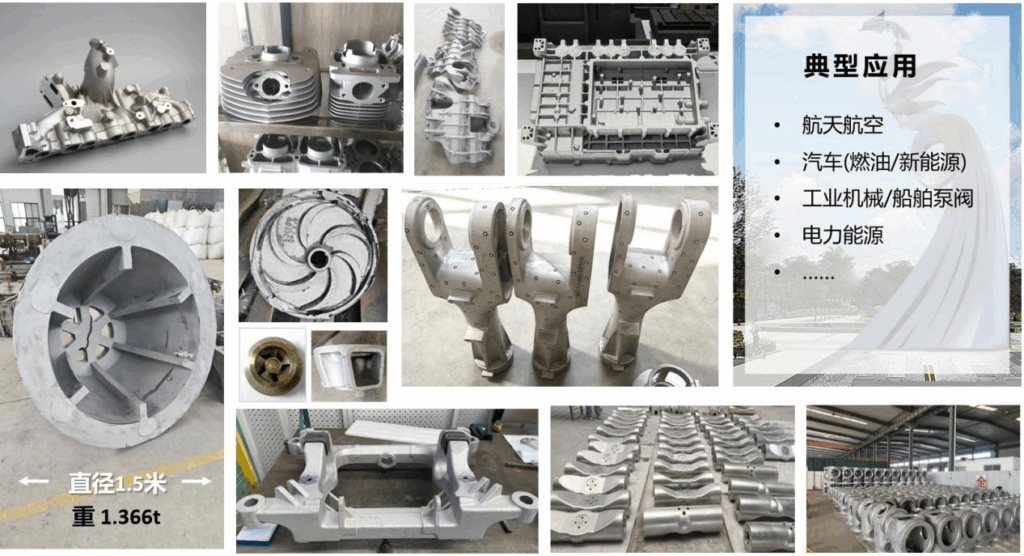

SANDY TECHNOLOGY's unique "SLS coated sand molding + 3DP resin sand molding"Combined sand manufacturing process (typical application scenarios of additive manufacturing of the Ministry of Industry and Information Technology), which can realize high-precision and high-strength integrated casting molding of complex structural parts (large-size, thin-walled, fine piping, etc.).

3DPSand casting processIt is mold-free and supports integrated molding of large-sized and complex structural parts in small and medium batches.

SLSSand casting processThe strength of the sand core reaches 4-6Mpa, and the precision is 0.1-0.2mm, which is suitable for complex pipeline and oil pipeline products.

SLSWax fine casting processThe company is mold-free, realizing rapid precision casting of thin-walled, large-sized and complex structural products.

Through the 3D casting factories and printing service centers in Xianyang, Shaanxi, Daiming, Hebei, Pingdingshan, Henan, Yulin, Guangxi, Rizhao, Shandong, Linzhou, Henan, Tongling, Anhui, etc., SANDI Technology has established the capability of full-size, multi-material, full-chain rapid manufacturing services, which can provide users in the fields of aerospace, electric power and energy, ships, pumps and valves, automobiles, rail transportation, construction machinery, etc., aluminum alloy, copper alloy, cast iron, aluminum alloy, copper alloy, cast iron, magnesium alloy, high-temperature alloy, titanium alloy and other materials, as well as casting sand, wax 3D printing services.

Service Hotline: 13811566237

3DEnabling Casting

Through the merger and acquisition and self-built foundry, SANDI Technology has opened up the "3D printing + casting" process to form a replicable and popularized demonstration model, helping traditional foundries to transform and upgrade, realizing green, intelligent, high-end casting, and practicing the national requirements for the development of new quality productivity. At present, three emperor technology 3D casting overall solution has been in the casting production in the mature commercialization of the application, take the lead in the introduction of 3D casting foundry, has established a green, flexible, high-end rapid casting capabilities, to achieve productivity, capacity, revenue doubling growth, but also significantly improve the production efficiency and quality of high-end complex castings, to broaden the scope of the business, increased to seize the market opportunities, the bottom line. Successfully transformed into a green fast casting demonstration plant.

[About SANDI TECHNOLOGY

3D Printing Technology, Inc. is a 3D printing equipment and rapid manufacturing service provider, a national specialized, special and new "small giant" enterprise, and a typical application scenario supplier of additive manufacturing of the Ministry of Industry and Information Technology (MIIT). At the same time has laser and binder jet 3D printing equipment and materials technology and application process, business covers the development and production of 3D printing equipment, 3D printing raw materials development and production, 3D printing process technology support services, rapid finished parts manufacturing services, etc., the establishment of a complete 3D printing additive manufacturing industry chain, which is widely used in aerospace, electric power and energy, ships, pumps and valves, automobiles, rail transportation, industrial machinery, 3C electronics, rehabilitation and transportation, and industrial machinery, 3C electronics, and industrial machinery, and industrial machinery, and industrial machinery, and industrial machinery, and 3C electronics, and rehabilitation and transportation, industrial machinery, 3C electronics, rehabilitation and medical treatment, education and scientific research, sculpture and cultural creation and other fields.

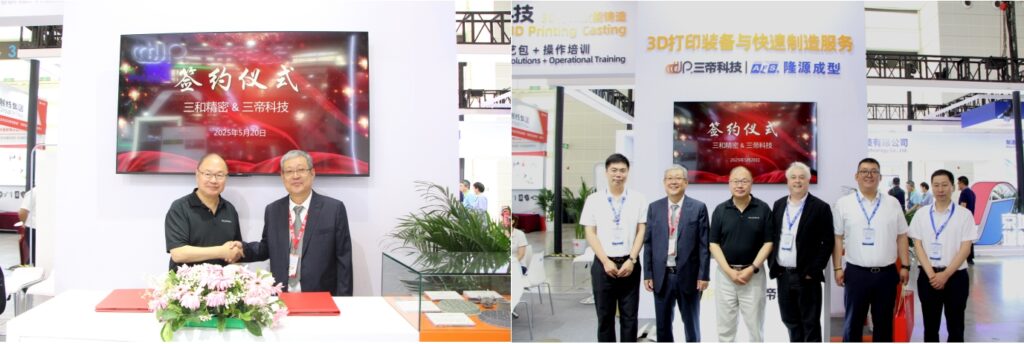

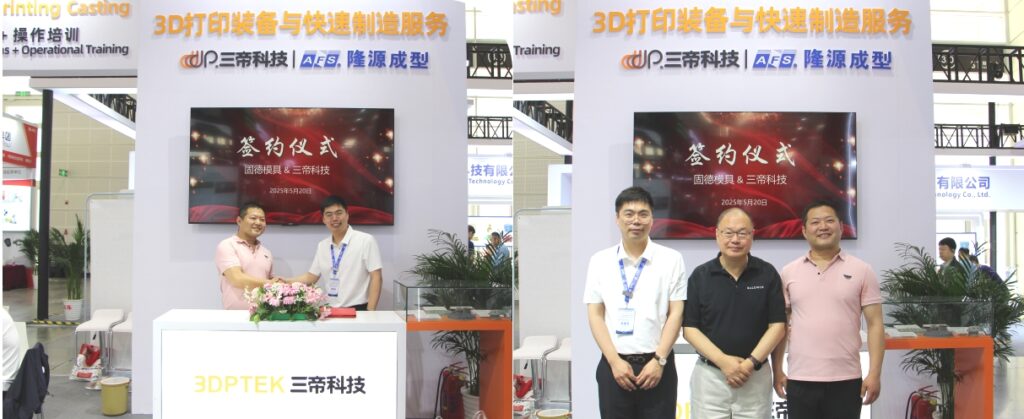

On May 20, 2025, Beijing SANDI Technology Co., Ltd. reached a strategic cooperation with Cangzhou Bohai Sanhe Precision Manufacturing Co., Ltd. and Goodyear Mould (Shenyang) Co., Ltd. on the in-depth application of 3DP sand printing technology in the field of casting and mold. The partners will rely on 3DP sand printing equipment independently developed by SANDI Technology to promote green, intelligent and high-end casting.

Figure: Sanhe Precision and SanDi Technology sign strategic cooperation agreement

Figure: Goodyear Mould and SANDI Technology signed a strategic cooperation agreement

Cangzhou Bohai Sanhe Precision Manufacturing Co., Ltd. is a high-end casting head enterprise formed by a joint venture of several enterprises, including Japan Concord Foundry and Tianjin Binrui Trading, focusing on the research, development and production of precision castings for intelligent valve bodies, aviation hydraulic systems, gearboxes and other precision castings. In this cooperation, Sanhe Precision will introduce 3DP sand printing equipment of SANDI Technology to optimize the product development process and improve the production efficiency of complex castings, further consolidate its leading position in the global precision casting market and accelerate the upgrade to intelligent manufacturing.

Goody Mould (Shenyang) Co., Ltd. is a leading precision mold manufacturer in China, focusing on the design and production of molds for complex curved structural components such as industrial machinery, marine pumps and valves. Goody Mould will introduce SANDI's 3DP sand printing equipment for rapid verification of metal molds before development, which will significantly shorten the product development cycle, reduce the cost of the molds, and further enhance its competitiveness in the high-end mold market.

As a leading provider of 3D printing equipment and additive manufacturing services in China, SANDI Technology is committed to providing users in the foundry industry with all-round support from process optimization to production verification through its self-developed 3DP sand printing and SLS sand/wax equipment. In order to meet diversified market demands, based on 30 years of accumulation of powder laying technology, SANDI Technology has formed a complete product line of sand printing equipment, including 1.6m, 1.8m, 2.5m, 4m and other size series, covering the full size of 3DP casting sand printing from millimeter to meter level, which can meet the manufacturing needs of products of different sizes and materials, and, with lower unit cost and shorter delivery time, can help users maximize productivity.

Figure: 3DP casting sand printing equipment independently developed by SANDY Technology3DPTEK-J1600Pro/J1600Plus/J1800/J2500/J4000

From May 20-23, SANDI Technology is showcasing oversized casting sand printing and a full range of 3D casting solutions on-site during the China International Casting Expo, welcome to visit SANDI's booth (Hall S8-A06, Tianjin National Convention and Exhibition Center) to exchange ideas!

On April 19, 2025, "Advanced Materials and Foundry New Technology Forum and the 10th Tianjin Foundry Annual Conference", organized by Tianjin Mechanical Engineering Society Foundry Branch and National Key Laboratory of Advanced Roll Materials and Composite Forming, was held at Beichen Campus of Hebei University of Technology. (hereinafter referred to as "SANDI") participated in the meeting as the support unit of this forum.

Figure: SANTI Technology serves asTianjin Mechanical Engineering Society Casting Branch (Tianjin Foundry Society) 10th Council Executive Director Unit

In the morning forum on the 19th, Dr. Zong Guisheng, Chairman of SANDI Technology, shared the oversized sand 3D printing solutions. For the aerospace, shipbuilding and heavy industry and other fields have long been plagued by ultra-large castings manufacturing problems, Dr. Zong Guisheng in-depth analysis of the bottlenecks of the traditional process in terms of efficiency, cost and quality, and focused on the revolutionary technological breakthroughs of SANDI Technology's self-developed 4-meter ultra-large-size 3DP sand printer 3DPTEK-J4000.

The equipment adopts sandbox-free flexible area molding technology, which breaks through the size limitation of traditional casting, and can support up to 4-meter sand manufacturing. Its core technical advantages are reflected in the following: 1. integrated molding of complex structures: through high-precision nozzles and intelligent algorithms, it realizes one-time molding of large-size, thin-walled, multi-dimensional curved surfaces and complex cavities (such as helical cooling water channels), breaking through the limitations of the traditional process on the design of the space; 2. high efficiency and low cost: compared with the traditional split casting, the production cycle is shortened by more than 50%, for example, a 1.25-ton aluminum alloy casting is compressed from 60 days to 15 days to complete the delivery of the traditional process; 3. economic optimization: the price of the equipment is only comparable to the equipment of the 2.5-meter class, and the open source material process supports the adjustment of the binder and the sand formula on demand, to further reduce the overall cost.

Photo: SANTI's booth, attracting many attendees to stop and exchange ideas

On the evening of 19th, the reception dinner of "3D Empowering Casting" hosted by SANDI Technology was held in Beichen Campus of Hebei University of Technology.

Photo: Prof. Liu Jinhai, Honorary Vice President of Tianjin Mechanical Engineering Society Casting Branch (Tianjin Foundry Society), and Jiang Qingjie, General Manager of 3D Equipment Department of Beijing SANDI Technology Co.

Photo: Dinner RaffleWarm atmosphere at the event

[About SANDI TECHNOLOGY

3D Printing Technology, Inc. is a 3D printing equipment and rapid manufacturing service provider, a national specialized, special and new "small giant" enterprise, and a typical application scenario supplier of additive manufacturing of the Ministry of Industry and Information Technology (MIIT). At the same time has laser and binder jet 3D printing equipment and materials technology and application process, three emperor technology business covers the development and production of 3D printing equipment, 3D printing raw materials development and production, 3D printing process technology support services, rapid finished parts manufacturing services, etc., to establish a complete 3D printing additive manufacturing industry chain, widely used in aerospace, electric power and energy, ships, pumps and valves, automobiles, rail transportation, industrial machinery, 3C additive manufacturing typical application scenarios, the Ministry of Industry and Information Technology, and the company is a leading supplier of additive manufacturing, rail transportation, industrial machinery, 3C electronics, education and scientific research, sculpture and cultural creation, rehabilitation and medical industries.

In the traditional foundry industry, sand mold making has always been a key link affecting productivity, cost and molding capability of complex structure castings. With the increasing market demand for high-precision, short-delivery and complex structure castings, the traditional manual molding and mold manufacturing methods have been difficult to meet modern manufacturing requirements. Sand 3D printers, as an advanced additive manufacturing technology, can directly print complex sand molds and cores without the need for molds, dramatically shortening the production cycle, reducing costs, and enhancing design freedom. In this article, we will discuss why traditional foundries should consider introducing sand 3D printing technology to enhance competitiveness, optimize production processes, and meet market demand for efficient and accurate casting. The following is written exclusively for foundry owners, and we hope it will inspire you.

--Customers want to do small quantities of trial parts, do a metal mold to 200,000, the result of the order is only 50 pieces, a calculation found that the mold cost more than the money earned, can only give up the order!

--The customer had an order for an aerospace part with honeycomb structure, and the traditional sand core assembly error was bigger than the part size, so it was a big headache to stare at the scrapped casting!

--Competitors with 3D printing took a well-known automotive battery pack orders, their own offer is lower than others 30% or did not win the bid, and finally inquired about the delivery of people faster than us 2 months, very helpless!

--Customers do not move to change the design of the warehouse piled up more than 300 sets of scrap molds, checking the accounts found that the mold inventory occupied half a year of profit, which is too painful to taste!

--Customers sent a complex structure of the pieces over, and said that the price is not a problem, an assessment found that the traditional casting process can not be done, looking at such a high value-added orders can only be given up!

Below we help all bosses one by one to sort out clearly, an article to let you fully understand the 3D printing sand casting technology!

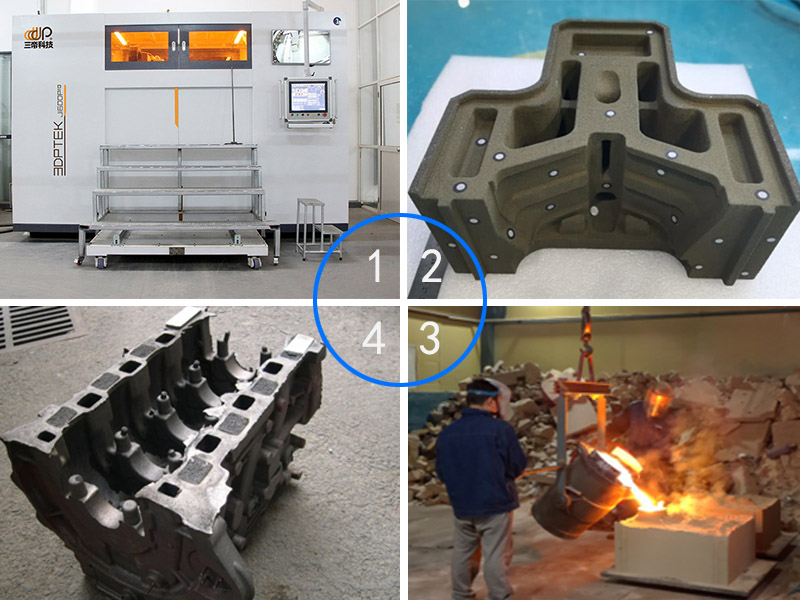

Sand 3D printing is a relatively new technology, simply put, is like building blocks, with special materials layer by layer "pile" out of the casting sand.

In the past, the traditional method of making sand molds may need to make molds first, and then use the molds to shape, the process is more complicated, and if you want to make some sand molds with very strange and complex shapes, it will be particularly difficult and costly. But sand 3D printing is different, it works with a 3D model in your computer. You input the data of the 3D model of the designed casting into the 3D printer, and the printer will, according to the shape and structure of the model, put special sand or sand-like materials, according to the layer by layer in a precise way and bonded up, just like using countless thin "sand pieces" gradually built into a complete sand mold. In this way, no matter how complex the shape, as long as it can be designed in the computer, it can be printed out, and the speed is quite fast, and do not need to make complex molds like the traditional method, can save a lot of time and cost it.

Sand 3D printing is usually done usingBinder Jetting (BJ)The basic principle is as follows:

The existence or birth of each technology must have its "mission". Commonly known as a solution to a particular problem, to meet market demand, this is the value of its existence. Below we take a look at the sand 3D printing technology to solve the thorny problems encountered in the traditional casting, as follows:

The price of a sand 3D printer is not cheap (usually the larger the size the more expensive), to buy is relatively cautious, especially small and medium-sized foundries. In order to help bosses to assess whether there is a need to buy, we have specially organized the following some evaluation points, to give the boss of the traditional foundry a reference, and then according to their own situation to decide whether to buy:

Considering that many traditional foundry enterprises may not be equipped with 3D printing sand casting related professionals, we have specially organized the position of workers need to have what aspects of the skills and usual job duties, so that factories in the recruitment of reference.

Professional Requirements:

Job Description:

In summary, sand 3D printing technology has brought many opportunities and changes for traditional foundries, which can effectively solve a series of thorny problems faced by the traditional casting process, such as the manufacturing of complex shaped parts, long production cycle, difficult to control the cost, poor casting accuracy and environmental protection pressure. Through a comprehensive assessment of production demand, cost-effectiveness, technical capabilities, market competition and environmental requirements, foundry owners can be more scientific and rational judgment whether to introduce sand 3D printer. Equipped with professional technical personnel, is to ensure that this technology in the foundry in the smooth landing, play the key to maximize performance.

In the increasingly competitive foundry market, take the initiative to embrace new technologies, and actively make changes, may be able to seize the first opportunity to realize the transformation and upgrading of enterprises and sustainable development. For traditional foundries, sand 3D printing technology is not only a technology change, but also a breakthrough in the development of bottlenecks, enhance core competitiveness of the perfect opportunity. I hope that all foundry bosses can combine the actual situation of their own enterprises, fully weigh the pros and cons, to make the most suitable for the long-term development of the enterprise's decision-making, so that the enterprise in the tide of the times to ride the waves, sailing to a broader market blue sea.

On March 10th, the 17th China International Powder Metallurgy, Cemented Carbide and Advanced Ceramics Exhibition (PM CHINA) was grandly opened in Shanghai World Expo Exhibition & Convention Center. (hereinafter referred to as "SANDI") brought BJ binder jet metal/ceramic and SLM gradient metal 3D printing solutions to the exhibition.

Photo: SANTI TECHNOLOGY live demonstration of BJ Binder Jet Metal Printer 3DPTEK-J160R

During the same period of the exhibition, SANDI Technology shared the theme report "Binder Jet 3D Printing Empowers Powder Metallurgy" at the Injection Molding Forum. The report pointed out that traditional powder injection molding (MIM) faces challenges such as high upfront investment, high cost of mold opening, and limited product sizes, while SANDI Technology realizes mold-less manufacturing, complex structures and large-size molding through binder jet 3D printing (BJM) technology, which provides powder metallurgy industry with a more efficient and low-cost solution.

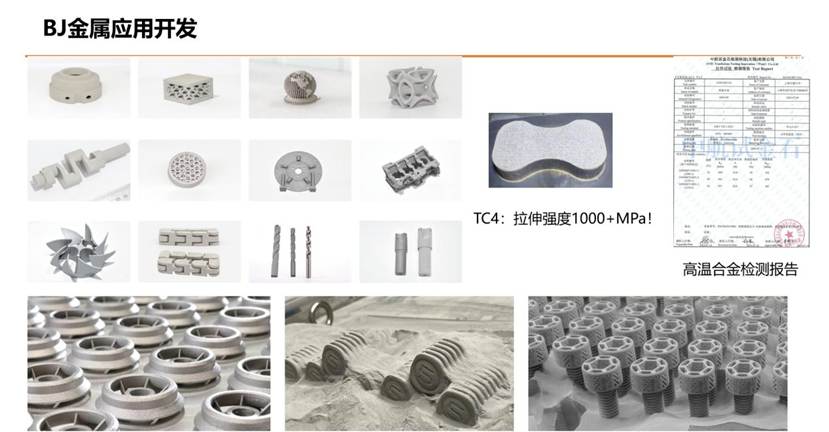

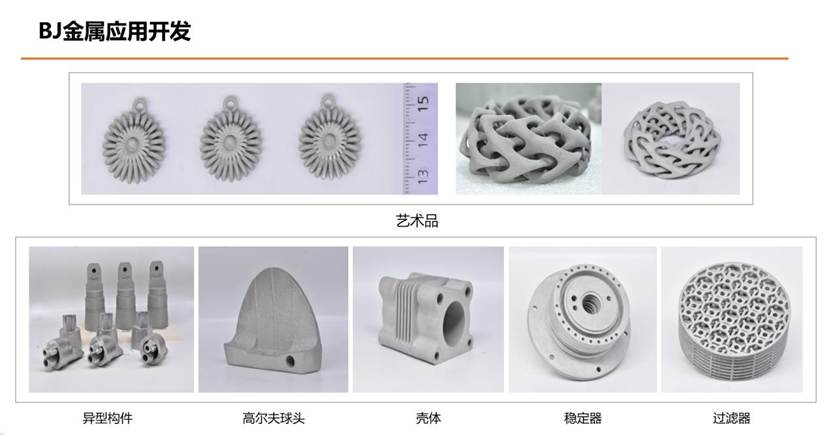

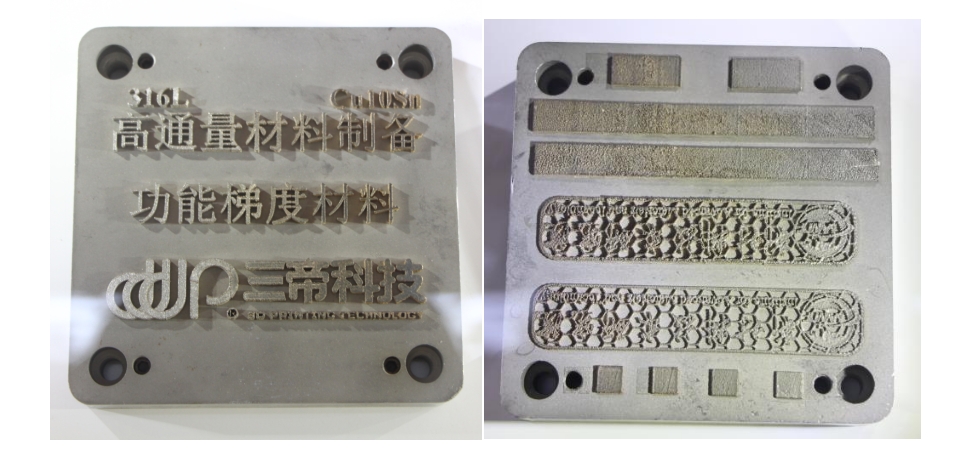

BJ Binder Jet Metal/Ceramic Printing Solutions

3DPTEK independently masters the key technologies of BJ technology equipment, materials and process, and has mature technology and experience in small particle size powder laying, powder bed density enhancement, high dimensional accuracy control, binder material system development, and degreasing sintering process. The company's self-developed 3DPTEK-J160R/J400P/J800P serialized binder jet printing equipment and its molding process integrates a precise feeding system, a high density powder laying system and a high-precision inkjet printing control system, which solves the key common technologies of small particle size and low mobility powder laying and molding density and breaks through the key technologies of high-resolution and high-precision inkjet control, and can realize 800-1200dpi high-resolution printing and molding, molding accuracy is better than ±0.1mm, molding efficiency up to 3600cc/h, the relevant technical indicators have reached the international advanced level.

Figure: BJ Metal/Ceramic Printer 3DPTEK-J160R, 3DPTEK-J400P/J800P

Meanwhile, SANDI Technology has gradually formed a sound molding process system for binder materials in years of BJ technology research. Based on more than 20 kinds of process formulas formed by two major types of water-based environmentally friendly binder and solvent-based high-efficiency binder, the company develops corresponding molding process and post-treatment process such as degreasing and sintering, realizing the molding process applicable to stainless steel, industrial mold steel, titanium alloy, copper alloy, high-temperature alloys, hard alloys and other metal materials, ceramic materials such as silicon carbide (SiC), as well as PMX crystalline waxes, inorganic salts, foodstuffs, medicines, polymers, composite materials and other non-metallic materials. Composite materials and other non-metallic materials molding process. Meanwhile, through the systematic research on high density degreasing and sintering molding process, we have realized the shape and property control of metal and ceramic products in the process of degreasing and sintering, and precisely controlled the quality of the finished products after degreasing and sintering, and the performance of the products is better than that of the mechanical properties of the MIM international material standard.

Figure: BJ Metal Printing

Figure: BJ Ceramic Printing

In addition, the three emperor technology joint Shenzhen Vocational Technical University, Shenzhen Tsinghua University Research Institute, Shanghai Jiao Tong University, University of Science and Technology Beijing and other research institutes related to the team to jointly carry out binder injection molding and other materials, process and application of basic technology research, to promote the industrialization of industrial molds, cutting tools, 3C electronics and other products, as well as complex and shaped large-size ceramic products in the field of industrialization and application.

SLMLaser Metal Printing Solutions

SANDI Technology has independently developed and launched SLM Selective Laser Melting Metal Printing Equipment AFS-M120/M400, Gradient Metal Equipment AFS-M120X(T), and Multi-material Increase/Decrease Equipment AFS-M300XAS, etc., and completed the molding of stainless steel/titanium alloys/aluminum alloys/mold steels/cobalt-chrome alloys/nickel-based alloys and other materials and process development.

Figure: SANDY Technology SLM (gradient) metal printing series equipment

Among them, the gradient metal printing equipment AFS-M120X(T) can be applied to the research and development of the properties of composite metal materials, and it can realize the continuous gradient accurate powder supply of two and more kinds of metal materials; it has the horizontal/vertical gradient change direction, which reduces the complexity of the process, saves the raw materials of the powder, and enhances the efficiency of research and development. It has a broad application prospect in the development of new materials in high throughput material preparation, aerospace, automotive, medical, mold processing and other fields. Multi-material additive and subtractive gradient metal AFS-M300XAS can be applied to the research and development of the properties of composite metal materials, up to 4 kinds of material gradient, the horizontal direction to achieve a continuous gradient change, the vertical direction to achieve the material composition switching or gradient change.

At present, SANDI has cooperated with many research institutes such as University of Science and Technology Beijing, Shandong University of Science and Technology, Lanzhou University of Science and Technology, Beijing University of Aeronautics and Astronautics, Beijing Iron and Steel Research Institute, Shenyang Institute of Automation, etc., and has been continuously providing advanced, reliable, and practical solutions for gradient functional metal materials.

Learn more about 3D Printing Enabled Powder Metallurgy Solutions, March 11-12, Shanghai World Expo Exhibition & Convention CenterSANDY TECHNOLOGY Booth: Hall H1, A735Welcome to the exchange!

In modern manufacturing, casting process has been an important method to produce complex metal parts. However, the traditional casting process faces many challenges, such as the difficulty of molding complex structures, limited customized production, long production cycle, difficult cost control, unstable product quality and environmental issues. With the rapid development of 3D printing technology, sand 3D printers have emerged as a revolutionary tool to solve these problems. In this article, we will delve into how sand 3D printers have changed the foundry industry and analyze the multiple advantages they bring (what core problems they solve).

Conventional casting processes often face enormous technical difficulties and high costs when manufacturing sand molds of complex shapes. For example, aircraft engine blades usually have fine and complex cooling channels inside, the traditional process of manufacturing such molds is extremely difficult. The sand 3D printer through digital modeling and layer-by-layer printing technology, can easily achieve the manufacture of complex shapes of sand molds, greatly reducing the technical threshold and cost.

With the rise of personalized consumption and niche markets, the demand for small-lot, customized castings is growing explosively. However, the traditional casting process, with its high mold opening costs and long customization cycle, is difficult to meet the market's rapid response needs. Sand 3D printers do not require molds and are able to quickly design and print sand molds according to customers' special specifications, shapes and performance requirements, greatly improving the flexibility and efficiency of customized production.

Traditional sand casting requires a lengthy process of designing the mold, manufacturing the mold, commissioning the mold, etc. The manufacturing cycle for large molds often exceeds several months. During the period may also be due to design changes or mold defects lead to rework, further extending the production cycle. Sand 3D printers do not need to make molds, directly according to the digital model printing, can significantly shorten the product development cycle, improve production efficiency.

In the traditional casting mold manufacturing process, the material waste is serious, and the material utilization rate of complex molds is less than 30%. In addition, from the molders to the molding workers, mold repair workers, the manpower investment is large, which further pushes up the cost. Sand 3D printer on-demand printing, accurate sand, material utilization rate of more than 90%. high degree of automation in the printing process, reducing the cost of manpower, significantly reducing production costs.

Traditional sand mold due to mold wear, parting surface fitting errors and other issues, casting size deviation often exceeds ± 1mm, subsequent machining allowance, material waste. Sand 3D printer by the digital model precision drive, sand size accuracy up to ± 0.5mm or less, reducing the machining process, reducing costs.

Traditional sand molds are prone to localized looseness, sand entrapment and other problems, resulting in uneven mechanical properties of castings, prone to cracks and other defects. Sand 3D printer can achieve uniform compactness, to avoid uneven sand loose, and at the same time, optimize the solidification process, significantly reduce shrinkage holes, shrinkage, to ensure stable and reliable internal quality of the casting, to enhance the performance and service life of the product.

Traditional casting mold manufacturing produces a large amount of waste metal, waste plastic, sand processing waste sand piles up. The annual capacity of 10,000 tons of castings of the factory, the annual emissions of waste sand more than 5,000 tons, high treatment costs and pollution of the environment. Sand 3D printer in the production, unused sand can be recycled and reuse, very little waste. In addition, the printing process does not require a large number of chemical binders, reducing the volatilization of harmful gases and improving the workshop environment.

Sand 3D printer can quickly respond to market demand, especially suitable for frequent re-modeling of small batch products. It allows foundries to quickly meet customers' individual customization needs and improve customer satisfaction and market competitiveness. At the same time, the sand 3D printer supports mass production, which can print a large number of high-quality sand molds in a short period of time to meet the needs of large-scale production and improve production efficiency and yield.

Sand 3D printing technology directly prints sand molds without opening molds, thus greatly reducing the cost of opening molds, especially suitable for small batch and complex structure production needs. In addition, sand 3D printing equipment can be operated with only simple training, and does not require a lot of manpower synergy, which can effectively reduce the dependence on skilled workers, so that foundries can easily cope with the recruitment difficulties and expensive labor problems.

Sand 3D printers are more accurate, such as the3DPTEKof 3D printing equipment, which means that the dimensional accuracy of castings is dramatically improved, the one-time pass rate of products is significantly increased, the scrap rate is reduced, and the foundry is allowed to utilize its resources more efficiently. At the same time, the 3D printed sand mold has better precision and surface quality, reduces the amount of grinding and finishing work, makes the production process cleaner, and improves product quality and process consistency.

With a compact body design, the sand 3D printer occupies a small area and is flexible to install, which is suitable for the different site layout requirements of small and medium-sized foundries. Modular production solutions can also support easy expansion of enterprises to achieve multi-machine linkage. Part of the sand 3D printer support digital monitoring system, business managers can monitor the production progress and equipment status in real time, to achieve a fully controllable production process, equipment operation data can be automatically stored to facilitate the optimization of production strategies.

The emergence of sand 3D printers not only solves many problems in the traditional casting process, but also brings unprecedented opportunities for the foundry industry. It provides foundries with strong competitiveness by improving production efficiency, reducing production costs, improving product quality and optimizing production management. With the continuous progress of technology, sand 3D printers will play an increasingly important role in the future of the manufacturing industry, promoting the foundry industry to a more efficient, more environmentally friendly and smarter direction.

This article explores sandbox-less 3D printers and how they can provide dimensional flexibility, high accuracy, cost-effectiveness, and design freedom from the limitations of traditional sandboxes to improve manufacturing efficiency. At the same time, it provides readers with an understanding of the innovative value and growth potential of sandbox-less 3D printers in the foundry sector.

The boxless 3D printer is so named because it eliminates the use of a traditional box in the sand 3D printing process, significantly differentiating it from conventional sand 3D printers. Here's more about it from a variety of perspectives:

The role and limitations of traditional sandboxesSandboxes are an indispensable part of the traditional sand casting process and some traditional sand 3D printing techniques. It is used to hold the sand, provide molding space for the sand model, ensure that the sand maintains a specific shape during the molding process, and ensure the integrity of the sand model during transportation and box closing. However, the fixed size of the sand box limits the size of the sand mold that can be produced, and the production and maintenance costs are high. For the complex structure of the sand mold, the sand box is difficult to design and manufacture, and it may also affect the heat dissipation and air permeability of the sand mold, which may affect the quality of the castings.

How sandless box 3D printers work: The sandbox-less 3D printer adopts sandbox-less flexible area molding technology, in which abrasive and binder are stacked and molded layer by layer by the nozzle directly on the worktable. The equipment has a precise sand spreading system, which can evenly spread the sand material in the printing area, and the nozzle accurately sprays the binder according to the model cross-section information, so that the sand particles are bonded to form the sand shape layer by layer. In this process, there is no need for a sand box to provide molding space and constraints, which greatly improves printing flexibility and freedom.

Basis of namingThe naming of the 3D printer directly reflects its core technical feature, which is that it is free from the constraints of the traditional sand box, creating a new mode of sand 3D printing. This naming scheme is simple and clear, highlighting the essential difference with the traditional sand 3D printing equipment, and emphasizing its unique advantage of realizing high-precision and high-efficiency manufacturing of sand patterns without the assistance of a sand box during the printing process.

There is a clear difference between the working principle of a boxless 3D printer and that of a traditional sand 3D printer. Traditional sand 3D printers rely on a fixed sand box to define the molding space, and rely on the sand box to provide partial support, and the print path is limited by the sand box; while sand box 3D printers use flexible area molding technology, expanding the printing platform on demand, breaking through the size limitations, and supplying the sand and binder with greater precision, and adjusting the internal sand buildup and binder injection to provide support, so the print path is more freely and flexibly planned, and it can effectively improve the printing efficiency and sand quality. It can effectively improve the printing efficiency and the quality of the sand mold.

The development of sandbox-free 3D printers in the foundry field is very promising, mainly in the following aspects:

Technological innovation and breakthroughs

Sandbox-free 3D printers continue to realize technological innovations, such as SANDI's 3DPTEK-J4000 Adoption of sandbox-less flexible area molding technology, can be customized to expand the printing platform, the maximum molding 4 meters of sand, to meet the production needs of 10 meters + level, breaking through the traditional casting equipment size limitations, for the manufacture of large and complex castings to provide the possibility of.

Significant cost advantages

On the one hand, the cost of ownership is reduced, as the price of 4-meter and larger boxless 3D printers is comparable to that of 2.5-meter machines, allowing companies to obtain larger sizes of abrasive molds at a lower cost per unit. On the other hand, material waste is reduced, as boxless 3D printers allow precise use of materials such as sand and binder, reducing production costs.

Strong growth in market demand

Aerospace, automotive, energy power and other fields of large, complex, high-precision castings demand continues to rise. For example, the manufacture of aircraft engine components, automotive engine block, etc., sandless 3D printers can meet the high-performance requirements for castings in these fields, the market potential is huge.

Significant increase in design freedom

The sandless box 3D printer can manufacture complex geometric shapes and cavities that are difficult to achieve by traditional methods, realizing parts integration and lightweight design, providing more space for product innovation and helping to improve product performance, reduce costs and enhance the market competitiveness of enterprises.

Significant increase in productivity

Compared to traditional mold making methods, sandbox-less 3D printing of sand molds or cores takes only a few hours to a few days, dramatically shortening the development and production cycle of new products, helping manufacturers respond faster to changes in market demand, and improving productivity and economic efficiency.

Superior environmental performance

Sandless 3D printers use materials on demand, reducing waste and disposal costs of leftover materials, and some of the equipment can use environmentally friendly materials and binders, which reduces environmental pollution, meets the requirements of sustainable development, and helps foundry companies to meet the increasingly stringent restrictions of environmental regulations.

Deepening Industrial Integration

The integration of sand box 3D printer and foundry is deepening, enterprises through mergers and acquisitions of foundries and other ways to open up the "3D printing + casting" process, to provide the whole industry chain overall solution, and promote the foundry industry to the green, intelligent, high-end direction of development.

If you are looking for a partner who can provide fast and high-quality casting services, Guangxi Yulin Foundry (under Beijing SANDI Technology) is undoubtedly a trustworthy choice. As a foundry dedicated to innovation and efficient production, Guangxi Yulin Foundry not only meets the diversified needs of our customers, but also stands out in the fiercely competitive market by virtue of our advanced technology and geographical advantages. Below are the core advantages and service highlights we can offer you:

Guangxi Yulin Foundry has realized a technological breakthrough in the field of casting with the introduction of 3DP sand printing technology. The technology allows for the rapid manufacture of complex sand molds, resulting in a significant reduction in casting production cycles. This innovative process can meet customer demand for rapid casting of cast iron and aluminum alloys, and is especially suitable for companies with high precision requirements for trial parts, small batch production and complex parts. Through 3DP printing technology, Guangxi Yulin Foundry not only improves the efficiency, but also ensures the quality and consistency of castings, saving time and cost for customers.

The location of a business is one of the most important considerations when choosing a supplier. Guangxi Yulin Foundry is located in the area connectingGuangdong-Hong Kong-Macao Greater Bay Areacap (a poem)Beibu Gulf Economic Zone (economic region including Beijing, Tianjin, Hebei, Liaoning and Shandong)The key corridor. With this unique location, we are able to respond quickly to orders from southern China while radiating to theASEAN markets. This is a hundred-billion-dollar machinery manufacturing market, which provides customers with a wide space for cooperation. Whether you are a domestic or international customer, you can enjoy convenient logistics and perfect supply chain services.

Guangxi Yulin Foundry has a strong production capacity, the annual output of high-performance aluminum alloy products up to2 million piecesThis capacity not only reflects our scale and strength, but also means that we can provide stable and continuous supply of products to our customers. This production capacity not only reflects the scale and strength of the company, but also means that we are able to provide our customers with a stable and continuous supply of products. Whether it is aluminum alloy parts of various specifications or customized needs, we can meet them efficiently.

South China and ASEAN region is in the stage of rapid development of machinery manufacturing industry, the demand for high quality casting products is growing. Guangxi Yulin Foundry is deeply committed to this market and has a deep understanding of the industry needs and development trends. Our casting products are widely used in automobile manufacturing, construction machinery, industrial equipment and many other fields, providing reliable support for local and regional machinery manufacturing enterprises.

Guangxi Yulin Foundry always adheres to the concept of "customer first, quality first" to provide customers with high quality casting products and services. Whether you need innovative technical support for rapid casting or stable supply of large quantities, we can provide you with the right solution. Choosing Guangxi Yulin Foundry is choosing efficiency, reliability and professionalism. We look forward to cooperating with you to create a brilliant future!

Anhui Tongling 3D Casting Center is a casting center focusing on metal art casting and precision manufacturing under Beijing SANDI Technology. As one of the first companies in China to successfully apply 3D printing precision casting technology to the casting of metal sculptures that rely on manual modeling, we have broken the limitations of traditional hand casting, significantly improved efficiency, while realizing an unprecedented degree of freedom of design, providing customers with innovative metal art and casting solutions.

Covering an area of 7,000 square meters, the 3D casting center in Tongling, Anhui Province is equipped with a variety of advanced casting processes and equipment, covering the whole process of production capacity from design to finished product. Whether it is the creation of complex metal sculptures or the manufacture of high-precision industrial castings, we are able to meet the diverse needs of our customers.

We have pioneered the introduction of 3D printing technology into the metal sculpture casting field, providing our customers with the following advantages:

We master a variety of advanced casting and processing technology, can be flexible according to customer needs to choose the most suitable process:

Anhui Tongling 3D Casting Center is committed to providing customers with technologically advanced and reliable quality metal art casting and precision manufacturing services. Whether you need to design complex urban sculptures, customize high-end artwork, or quickly prototype high-precision industrial parts, we can provide you with the best solutions.

We are not only a manufacturer, but also a creative realizer in cooperation. Through advanced technology, professional service and strong production capacity, we look forward to working with you to create more wonderful works!