"There are too many orders to do over, just finalized an order with a northeastern customer in the morning, the subject amount is more than 3 million yuan." February 18, spring snow covered the earth, Wugong County Xin Xin Nonferrous Metal Casting Co., Ltd (hereinafter referred to as Xin Xin casting) production workshop a busy scene, this small and medium-sized enterprise has the first introduction of 3DP sand printing rapid casting advanced technology foundry in Shaanxi Province, since the beginning of the spring, the production orders continue to come.

"With the technical support of the domestic 3D printing benchmark enterprise, now we can produce all kinds of complex structure molds, the efficiency has been increased by two times, and the cost has been reduced by half. At the same time, using the sales channels of the upstream enterprises, our casting products are also sold all over the country." Xinxin casting head Tan Dawei said, Gree Electric Appliances, Chery Automobile and other enterprises are their customers.

Just before the first half of last year, the non-ferrous metal casting enterprises are still urgently seeking "breakthrough" way. "The traditional casting process of high energy consumption, high pollution, product precision can not keep up with the requirements of the advanced manufacturing industry, in the country vigorously advocate the development of green casting industry in the context of the traditional casting enterprise development and transformation of the pressure is great." Tan Dawei said, in Wugong County, like them there are five enterprises, are facing similar development difficulties.

Casting industry is the backbone of modern manufacturing, a car has more than 15% parts produced by casting. To high-end, green, intelligent close, is the traditional casting enterprises to achieve high-quality development of the inevitable choice.

From the traditional casting development difficulties, to intelligent transformation of products into market recognition of the "meat and potatoes", Xin Xin casting is how to ride on the 3D printing green casting of the express, so as to enter the transformation and upgrading of the traditional casting enterprises in the fast lane?

It started with an "encounter" between Xianyang Municipal Bureau of Science and Technology and CICC.

"When we docked with CICC Capital for the transformation fund of scientific and technological achievements, we learned that Beijing SANDI Technology Co., Ltd (hereinafter referred to as SANDI Technology), which is led by CICC Capital, had the idea of merging and acquiring casting enterprises, and then we shared this information with the casting enterprises in Xianyang City, and the relevant enterprises were very interested in it." Shen Yan, a staff member of the Science and Technology Bureau of Xianyang City, said that they provided a list of casting enterprises in Xianyang City to SANDI Technology, which paved the way for in-depth cooperation afterward.

At the same time, Wugong County, then in charge of industry and investment promotion work of the deputy governor Liu Wei in the three emperor science and technology chairman Zong Guisheng on the cooperation matters in-depth discussions, after the Wugong County Governor Yao Junfeng also led the relevant departments to Shenzhen to visit the three emperor science and technology companies, and further strengthened the confidence of the two sides of the cooperation.

In this way, a Beijing science and technology, capital and the traditional casting enterprises in Xianyang bridge up. At that time, three emperor science and technology in other parts of the country to investigate the object of cooperation, and Xin Xin casting can seize this opportunity to obtain favor, the key to its success lies in the "efficiency".

"Beijing's enterprises are very efficient, and after indicating our intention to cooperate, we quickly contacted SanDi Technology, and we finalized our partnership in two months' time." Tan Dawei said that with the cooperation bridge built by the Science and Technology Bureau of Xianyang City, their two enterprises with strong complementarity in business quickly found an entry point for cooperation.

"We are interested in Xinxin Casting's more than thirty years of industry accumulation, good business conditions, mature technology processes and the ability to provide efficient, continuous and high-quality services to users. All of these qualities fit well with the strategic layout of SANDI Technology's commitment to building a new ecology for the 3D printing green casting industry." Li Changqing, Deputy General Manager of SANDI Technology, said.

In addition, according to Li Changqing, Xi'an and Xianyang have more scientific research institutes and R&D enterprises, and such customers have a greater market demand for rapid trial production and project validation, and their cooperation with Xinxin Casting located in Wugong County of Xianyang City can further extend their market reach in Xi'an and neighboring cities; on the other hand, the business environment in Shaanxi is getting better and better, and the Science and Technology Bureau of Xianyang Municipality has provided them with On the other hand, the business environment in Shaanxi is getting better and better, and the Science and Technology Bureau of Xianyang City has provided them with great support to look for cooperation opportunities.

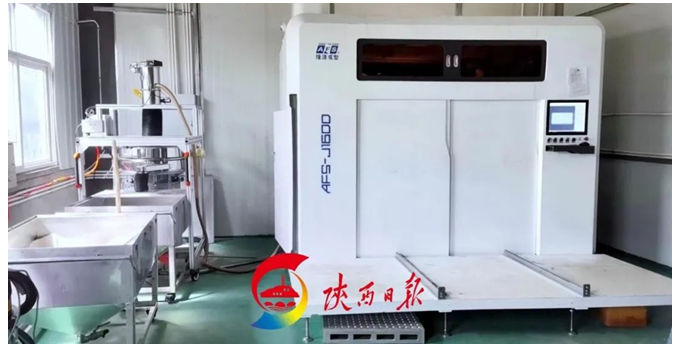

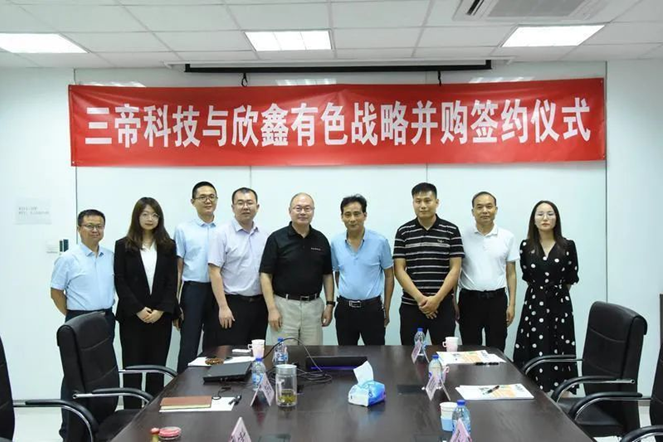

After 2 months of negotiation, the two sides 5 times consultation, this CICC capital and the Science and Technology Bureau of Xianyang City, "matchmaking", to realize the innovation elements of cross-regional integration of the cooperation was finalized. Xinxin casting became a subsidiary of three emperor technology holding, three emperor technology in Xinxin casting into the province's first 3DP inkjet sand printing equipment.

"The equipment can realize moldless molding, replacing the traditional casting production line in the mold manufacturing and casting manufacturing links, eliminating the cost and time of opening the mold, eliminating the unreasonable design of the mold and the risk caused by the repair of the mold, high-precision integrated molding, which can be eliminated by splitting the mold, the quality risk caused by the group mold." Xin Xin casting Tan Dawei introduction, the technology can significantly shorten the cycle of product development and trial production, saving development costs, accelerate the time to market, applicable to aerospace, automotive, motorcycle, rail transportation, ship pumps and valves and other fields.

"'3D printing + casting' gives us wings, not only further strengthens Xinxin Casting's advantages in high-end complex castings, but also greatly expands Xinxin Casting's business scope and market share, making mass production of high-end castings possible." Tan Dawei said, at present, Xinxin Casting's new plant is under construction, after the completion of the plan to invest in another 8 to 10 sets of 3D printing equipment to further meet market demand.

According to Ma Zhengwei, Executive General Manager of CICC Capital, the in-depth cooperation between SANDI Technology and Xinxin Casting is a positive attempt for small and medium-sized foundry enterprises in the transition period to implement intelligent transformation based on 3D printing technology and establish green, flexible and high-end casting capabilities.

"At present, in the context of fully promoting the construction of the core area of the Qinchuangyuan Innovation Driving Platform Xianyang, Xianyang City empowers traditional industries through science and technology, realizes the 'government, industry, academia, research and financial services' resonance at the same frequency by means of three-dimensional linkage, and links enterprises, universities, institutes, and financial service institutions with the market as an intangible hand, to Helping Xianyang city's economic transformation and upgrading to achieve high-quality development." Yang Chongfeng, director of the Science and Technology Bureau of Xianyang City, said. (Source: Shaanxi Daily) (Author: Liu Kun)