After nearly 40 years of development, 3D printing technology has become a powerful tool for advanced manufacturing nowadays, with great development potential. According to Wholers data statistics, the global 3D printing market reached $15.244 billion in 2021, with a compound annual growth rate of 20.4%. According to the China Additive Manufacturing Industry Alliance data statistics, China's 3D printing enterprise revenue reached 26.5 billion yuan in 2021, with an average annual growth rate of 30%, which is higher than the global average growth rate, showing the world's first manufacturing The big country's attention to new manufacturing technologies and achievements.

It can be seen that the market growth rate of 3D printing is quite high, the whole industry scale is growing year by year, but compared with other industries, 3D printing is still a small industry. The reason for this is that the main constraints on the printing efficiency of 3D printing and material costs. For example, based on "point scanning" laser powder bed molten metal 3D printing technology, its aerospace, automotive, military, molds, medical and other fields of small quantities of precision metal parts manufacturing has many applications, but also compared to traditional manufacturing technology has more advantages, but for most industrial users, 3D printing to get a larger scale industrialized Application, there is an urgent need to solve the "slow and expensive" problem.

Binder Jetting (Binder Jetting/3DP, hereinafter referred to as BJ) is a high-efficiency, low-cost "line scanning" 3D printing technology, as early as 1993 was born in the United States at the Massachusetts Institute of Technology, due to the higher threshold of the process, the industry chain is much longer, the development process of the BJ technology lags behind the "dot scan" laser 3D printing technology. "Point scanning" laser 3D printing technology, but by virtue of efficiency and cost advantages, BJ technology is full of energy. In recent years, with a series of technological breakthroughs in the field of BJ, especially the successful development of BJ metal, once again by the industry's widespread attention, known as "Additive 2.0" technology. According to a SmarTech report, by 2030, indirect metal printing technologies such as binder jet 3D printing will realize an output value of 54 billion U.S. dollars (about 350 billion yuan).

Internationally, Desktop Metal, HP, Digital Metal and other companies in the past five years have completed the technical development of BJ metal technology, to achieve a certain degree of industrialization and application. Domestic BJ technology started later, but as a manufacturing country, China's market demand for BJ technology is more urgent, especially from the MIM (Metal Injection Molding) industry for rapid prototyping and small and medium-sized mass production needs. In this context, the rapid development of domestic BJ technology. It is understood that there are several domestic enterprises to BJ as a research project, of which, Beijing Longyuan Automatic Molding System Co., Ltd. (SANDI's subsidiary companies, hereinafter referred to as "Longyuan molding") has been put on the market equipment.

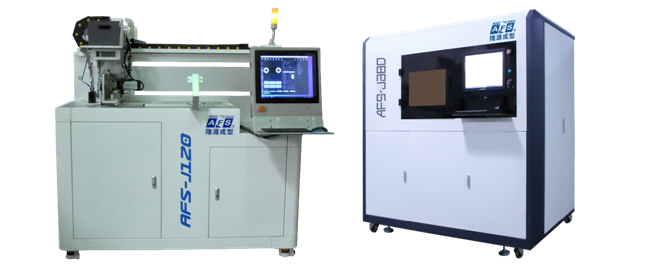

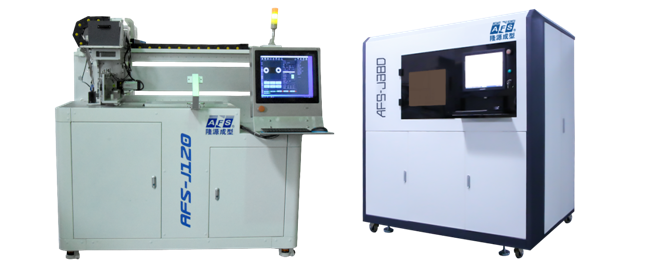

Longyuan Molding Company, a leading 3D printing technology company in China, completed the development of BJ metal technology and launched AFS-J120 and AFS-J380 equipment during 2018-2020. The equipments are built with integrated small particle size (5~15μm) low-fluidity powder precise feeding system, new powder spreading roller pressure system and high-precision inkjet printing system (1200dpi), which can realize ±0.1mm printing precision, >3600cc/h printing speed and >55% green blank density, and the relevant technical indexes have reached the international advanced level.

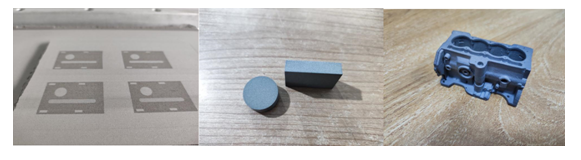

On the basis of the equipment, Longyuan Forming has successfully developed a series of BJ-specific binder formulations, which are suitable for more than 20 kinds of matrix materials, such as iron-based alloys, light metal alloys, organic glass, ceramics and so on. The team has conducted systematic research and analysis on the physical and chemical properties of the binder and the interaction between the binder and the powder, among which the water-based binder has the characteristics of green environmental protection, sintering low carbon and oxygen residue, etc., which has a good application effect. The degreasing and sintering process is a necessary back-end process to complete the manufacturing of BJ metals. The degreasing and sintering properties of the relevant BJ metal materials of Longyuan Forming have reached the international material standards of the MIM industry, and have the conditions for industrialization and application.

Binder jet metal 3D printing technology is considered to be one of the best ways to realize mass production of metal 3D printing due to its high printing efficiency, low material cost, cost-effective equipment, no additional support, and suitability for batch production, etc. The layout of Longyuan Forming in this field is also the implementation of its development concept of "platform + ecology" based on the core technology of 3D printing. The layout of Longyuan molding in this field is also based on the core technology of 3D printing, to create a "platform + ecological" development concept of practice.